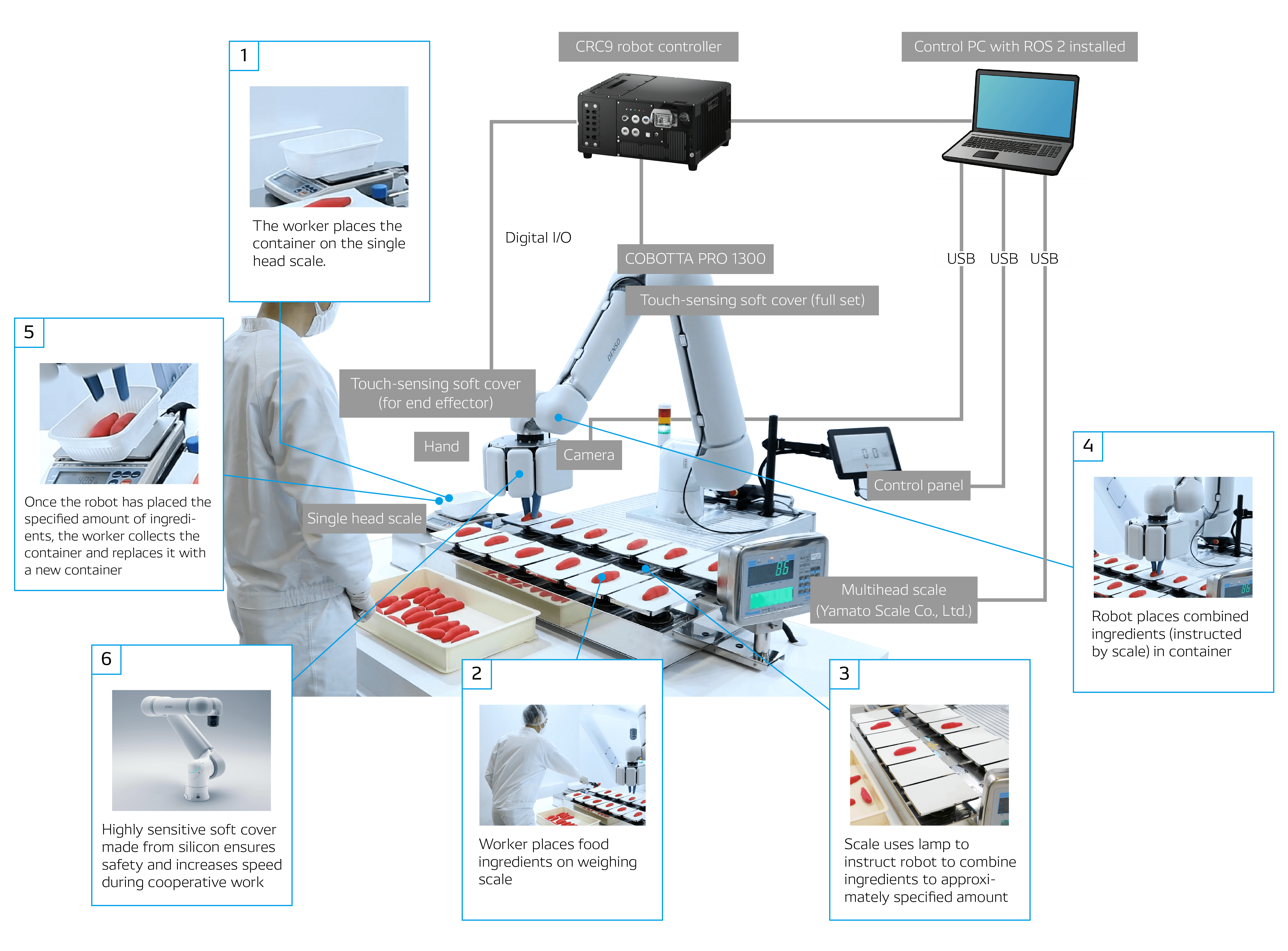

●Weighing process during food production, a dedicated machine must often be installed or work must be manually done by workers, making it difficult to meet cost requirements or ensure sufficient space and personnel.

●It is difficult to automate tasks involving gripping or placing food ingredients of irregular shapes.

●It is difficult to introduce cooperative measurement with a robot because it would not satisfy internal standards for safety or speed.

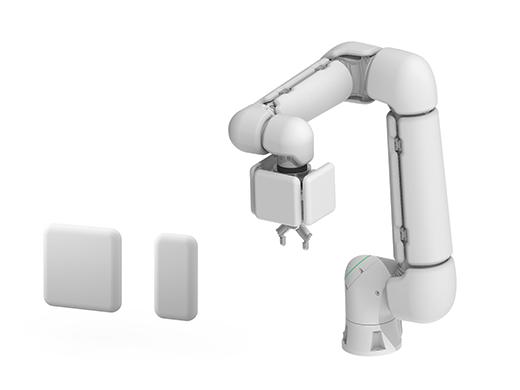

Weighing food ingredients on the multihead scale once required the work of two workers. COBOTTA PRO replaces one of those workers, reducing manpower.

It can work safely beside workers without any need to install a safety fence, even in food production plants with limited space.

The soft hand securely holds food ingredients that would otherwise easily collapse when using a conveyor or feeder.

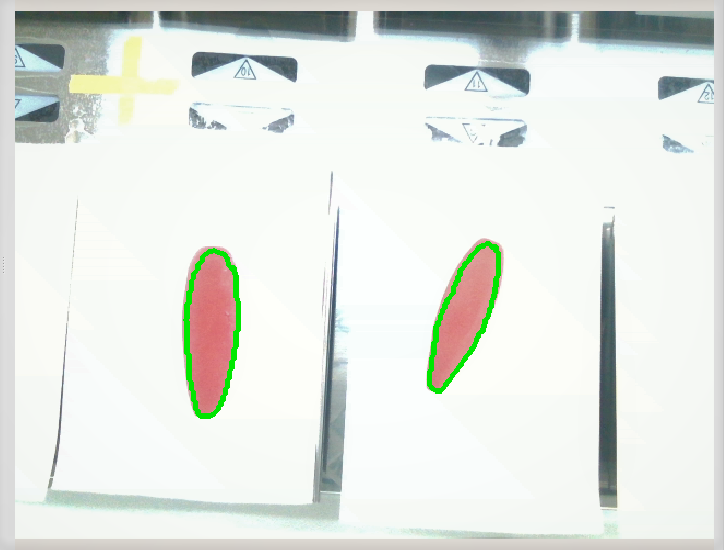

The system accurately recognizes where to grip food ingredients by obtaining positional data from the scale and utilizing a 3D camera.

*The 3D camera is installed inside the end effector touch-sensing soft cover.

ROS 2 is used to control and monitor robot operation, image processing, and combined weighing, allowing the robot to operate in a way that suits site conditions.

If the robot is moving to collect a food ingredient from the weighing scale but a worker picks the same ingredient from the scale, the robot changes its target and approaches a different weighing scale.

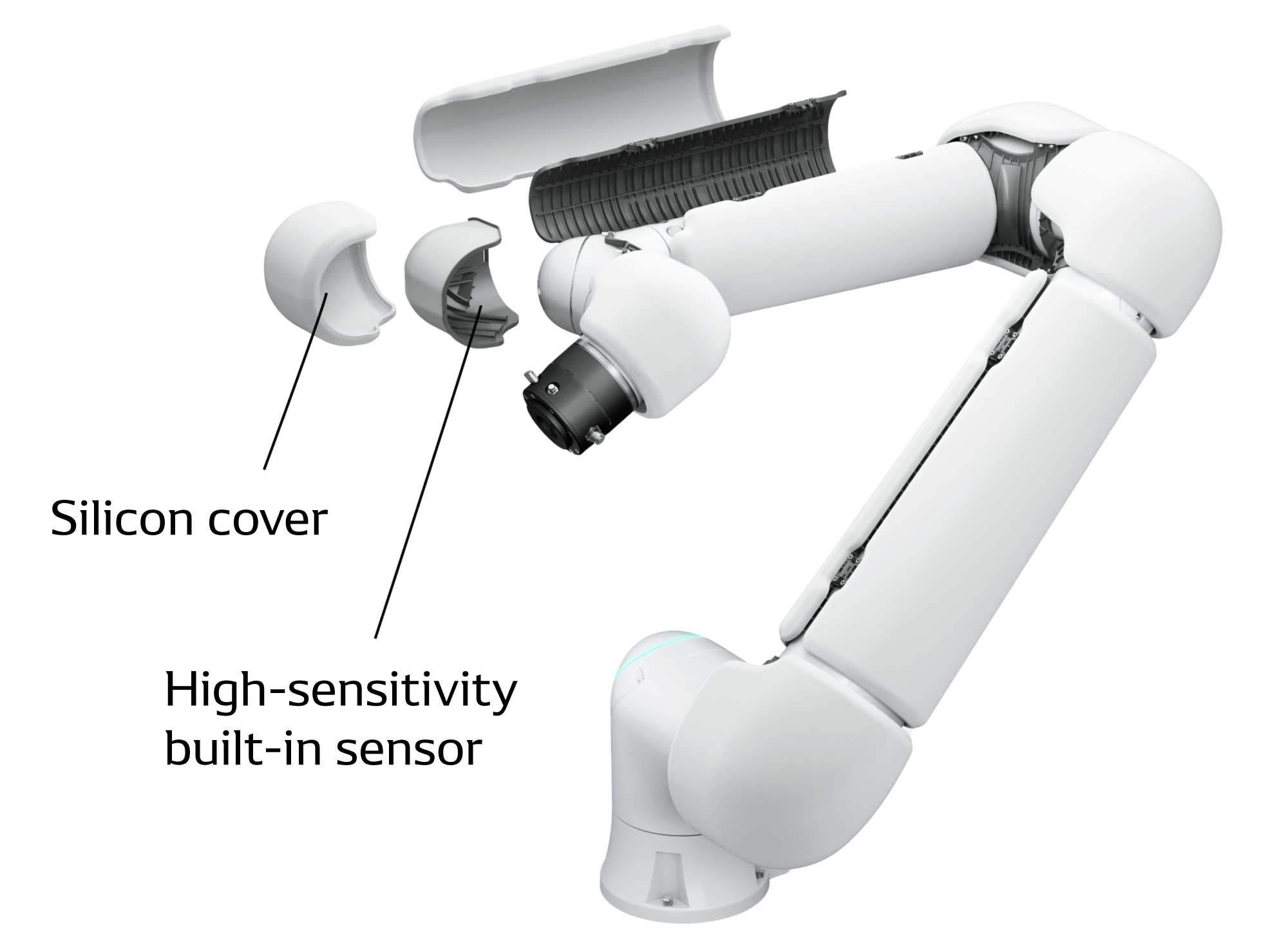

The soft cover is capable of detecting touch at a high level of sensitivity. This can help to increase speed during operation when working with a worker, further increasing productivity. The cover can be attached near the hand, where the robot is most likely to make contact with a worker. With the soft cover attached, the robot can operate at a maximum speed of 2,000 mm/s.

The soft cover can be attached up to the end effector. When a collision is detected, the built-in sensor reacts quickly to immediately stop the robot. Attaching the soft cover can help increase speed during operations when working with a worker, which can further increase productivity.

【FOOMA JAPAN 2023】DENSO WAVE Booth Report

If you have not registered

The services on this member site are available only for registered customers.