No matter how much advanced functionality a robot controller offers, those benefits will be undermined if the development environment changes or becomes more difficult to use. That’s especially true in the field of manufacturing equipment, where it’s difficult to change hardware that’s expected to operate over decades-long timeframes.

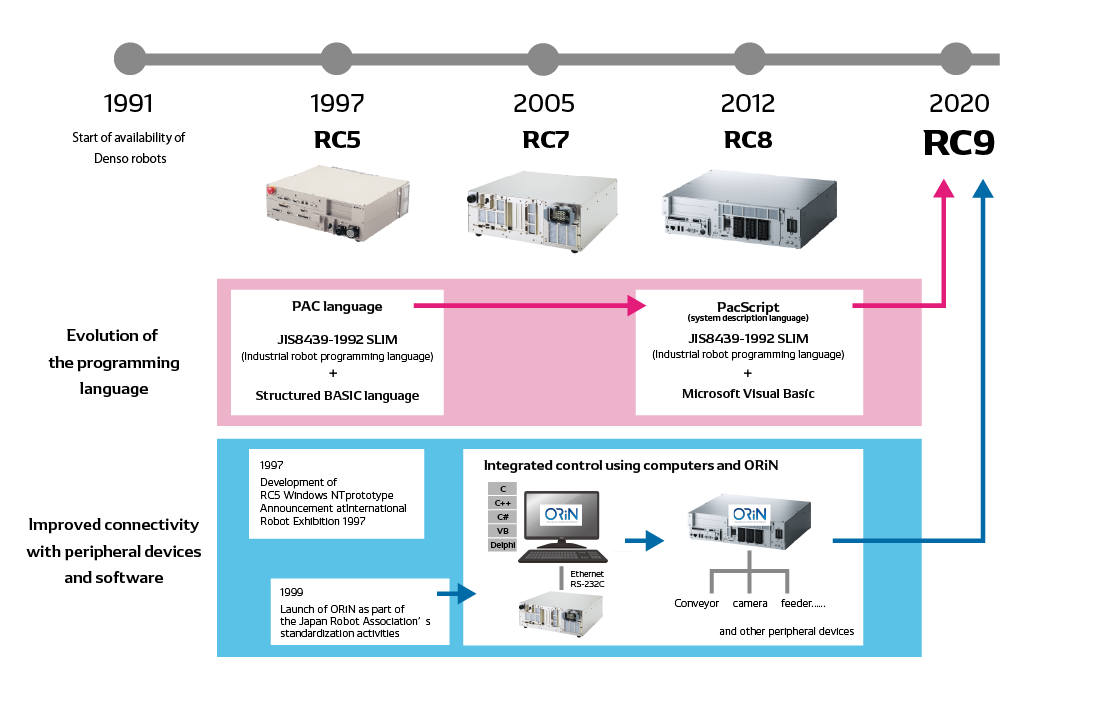

The RC9 Robot Controller inherits the open and powerful development environment whose evolution has been driven by Denso robots to date, allowing new functions to be developed in the same environment as has been used until now.

As explored in another article, a key strength of Denso robots is their powerful and open development environment. Of key importance to that environment are Denso’s robotics language, known as PacScript, and ORiN middleware.

PacScript, a programming language for controlling Denso robots, brings the accessibility of Microsoft’s Visual Basic to SLIM, a programming language designed for use with industrial robots. As a result, it offers a wealth of commands above and beyond robot operation, including flow control and arithmetic functions.

ORiN is middleware that provides a standard communications interface for accessing factory automation hardware like robots, databases, and other resources. ORiN smooths out manufacturer-specific differences in the methods used to control equipment to give engineers a familiar development environment, delivering substantial savings in man-hours spent on equipment launches and specifications changes.

With RC8, Denso provided a powerful development environment with about 450 commands (PacSript) and about 200 providers (ORiN).

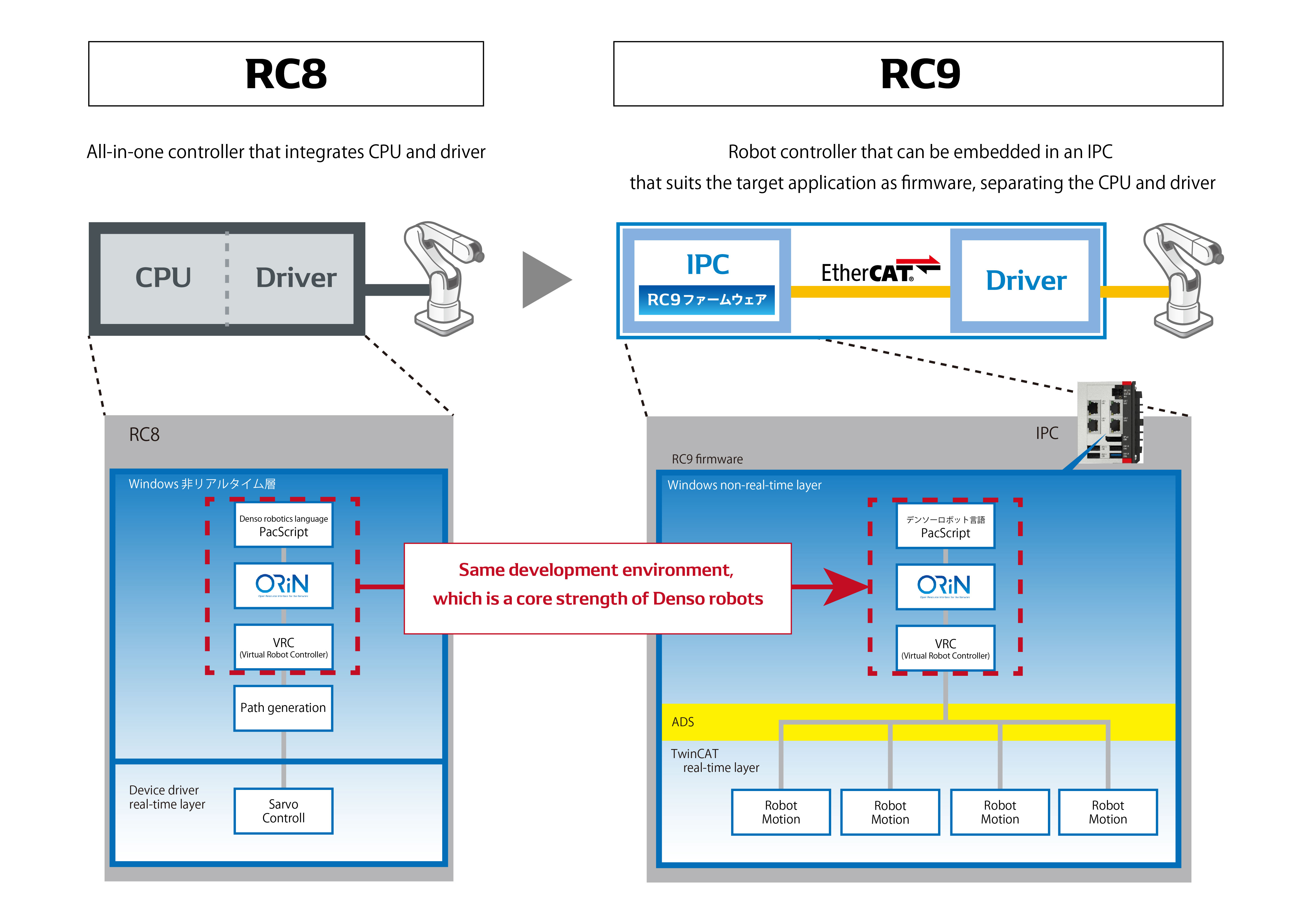

Let’s compare the RC8 and RC9 architectures.

The RC8 high-performance robot controller, which has been available for some time, is an all-in-one controller that integrates the CPU and driver. Internally, it consists of Windows (non-real-time layer) and device driver (real-time layer) components. The Windows layer includes ORiN and VRC middleware, and paths are generated based on those elements.

By contrast, RC9 uses a new architecture with separate CPU and driver components that are connected by EtherCAT. Internally, it consists of Windows (non-real-time layer) and TwinCAT (real-time layer) elements.

Despite its new architecture, the RC9 retains the same configuration for ORiN, VRC, and PacScript as the RC8 (shown in red), and it inherits the open development environment that customers have come to expect as a core strength of Denso robots. The biggest difference is found in path generation, which is carried out by the TwinCAT real-time layer instead of the Windows layer, accelerating the process compared to RC8.

True to its goal of engineering a robot controller that provides not only advanced functionality, but also easy programming and operation, Denso provides a variety of optional products and functions.

Smart TP is a teaching pendant designed for use with the RC9. A larger screen and new, easy-to-grip form factor provide improved operability. Unlike the previous teaching pendant, which only functioned as a display (VGA), Smart TP features an embedded CPU and operating system, allowing applications like a WINCAPS Plus UI to be added and displayed.

Additionally, the RC9 supports the TC3 HMI, allowing anyone to create intuitive graphical control panels. Since these control panels can be displayed on the Smart TP, equipment other than PLC-controlled robots (peripheral equipment like conveyors) can be operated from the Smart TP, which can be used as a control panel for entire systems.

Despite such new functionality, the development environment has not changed significantly. For example, WINCAPS III (software for creating robot programs) can still be used, and the teaching pendant interface remains compatible with the RC8, facilitating the same user experience as in the past.

This optional function aids in teaching and operation by causing a robot installed inside a safety fence to track a user’s manipulation of a COBOTTA collaborative robot. This extremely simple architecture requires only that the COBOTTA and slave robot be connected with an EtherNet cable. Functionality is available to allocate the COBOTTA’s “open/close gripper” button to operate the slave robot’s gripper, and to detect proximity to a virtual fence so that the COBOTTA reacts to attempts to move the slave robot out of a set area by warning the user. The setup makes it more intuitive to teach the slave robot by eliminating the need to think about coordinate systems while manipulating it. And since it allows remote operation of robots in clean environments, for example in pharmaceutical manufacturing processes, or hazardous settings like welding processes, it helps keep workers clean and environments uncontaminated.

Explore the following articles to delve more deeply into RC9 features.

If you have not registered

The services on this member site are available only for registered customers.