●Deep-frying kitchens at food plants posed risks, including heat exhaustion due to the hot, humid work environment and burns caused by hot oil.

●The simplicity of the tasks being performed and the demanding nature of the hot environment posed challenges for worker recruitment.

By using the COBOTTA PRO high-speed collaborative robot, the system can be embedded at locations where human workers performed manual tasks on manufacturing lines at existing plants.

It can be deployed in a small amount of space, without requiring a safety fence.

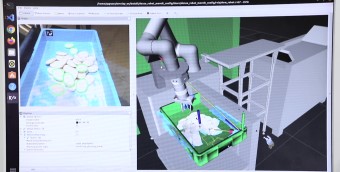

An AI vision system from RT Corporation is used to recognize irregularly shaped frozen food items piled on food trays, grip them with one of the company’s electric hands, and align them on a conveyor. The hand’s torque value is measured by the electric hand control box, which controls the opening and closing of the hand. In this application, robot operation, image processing, opening and closing of the hand, and conveyor operation are controlled using ROS, allowing the conveyor to operate appropriately as food items are placed in the fryer.

A jacket* designed specifically for the COBOTTA PRO accommodates the hygienic environment required at a food plant. The jacket protects food items from grease splatter.

*Currently under development.

Picking irregularly shaped or soft objects using 3D vision and a pressure sensor-equipped gripper

If you have not registered

The services on this member site are available only for registered customers.