What is ease of use in the first place?

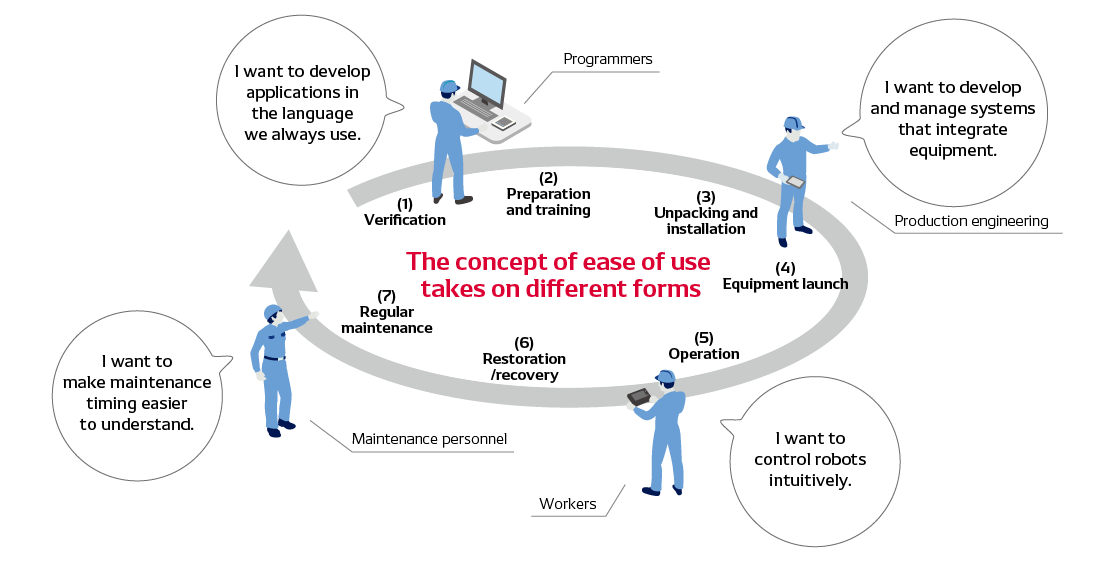

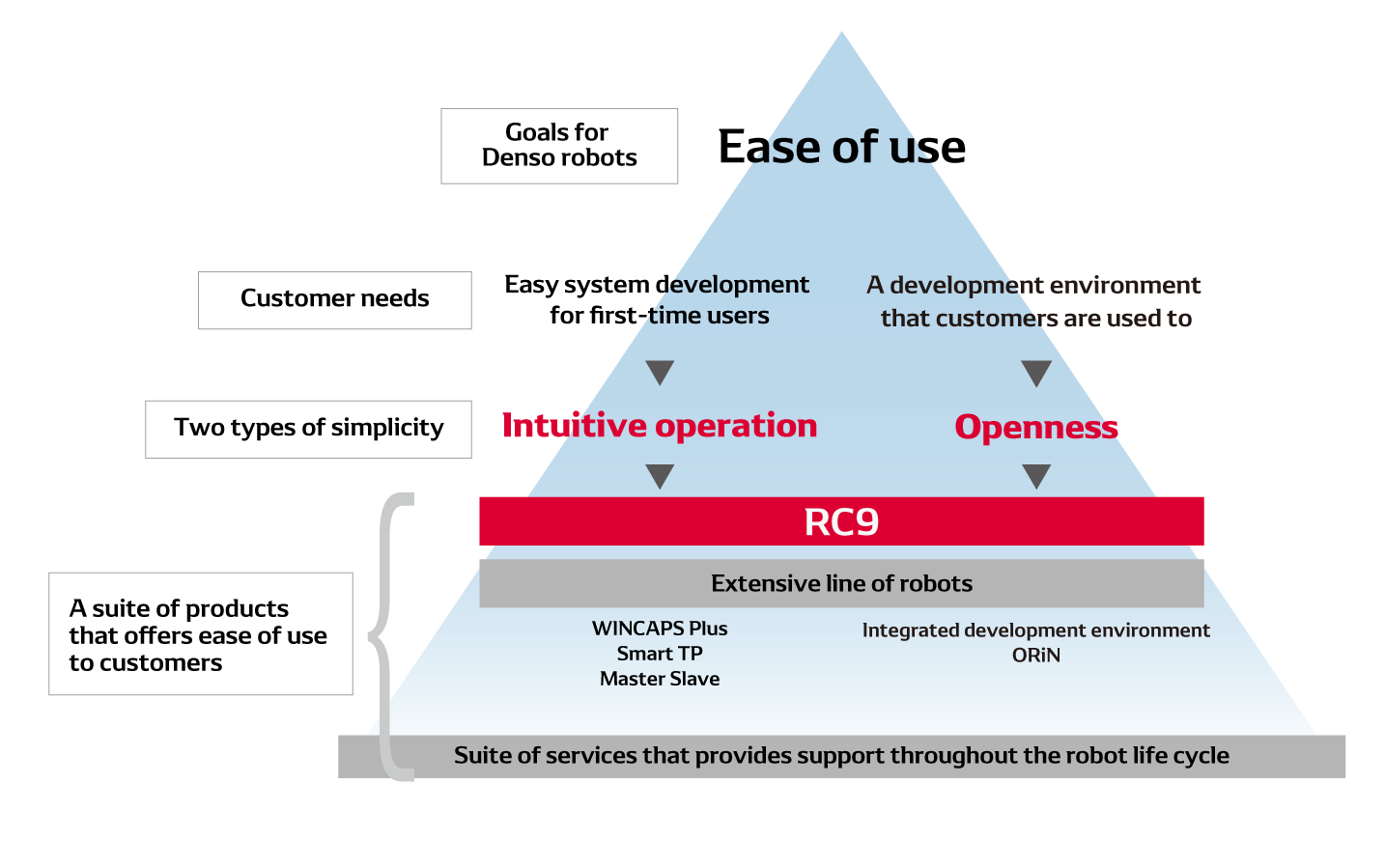

People naturally gravitate to tools they’re used to, and that tendency extends to the programming and operation of robots. For example, people who have no experience with robots may find that they prefer tools that control these devices in an intuitive, easy-to-understand manner, as illustrated in the above figure. By contrast, others may prefer to continue using conventional approaches, while still others, particularly engineers, may wish to create applications freely using software they’ve developed themselves. We recognize that the concept of ease of use takes on different forms depending on robot use cases, application complexity, and the goals of the people who are involved.

As a result, we believe that providing ease of use to everyone who’s involved with robots means offering an extensive selection of robots that can accommodate a broad range of applications, an open development environment, and software, optional products, and support services to aid in their use.

The openness to accommodate all manner of applications and development environments is essential in order to provide ease of use for robots.

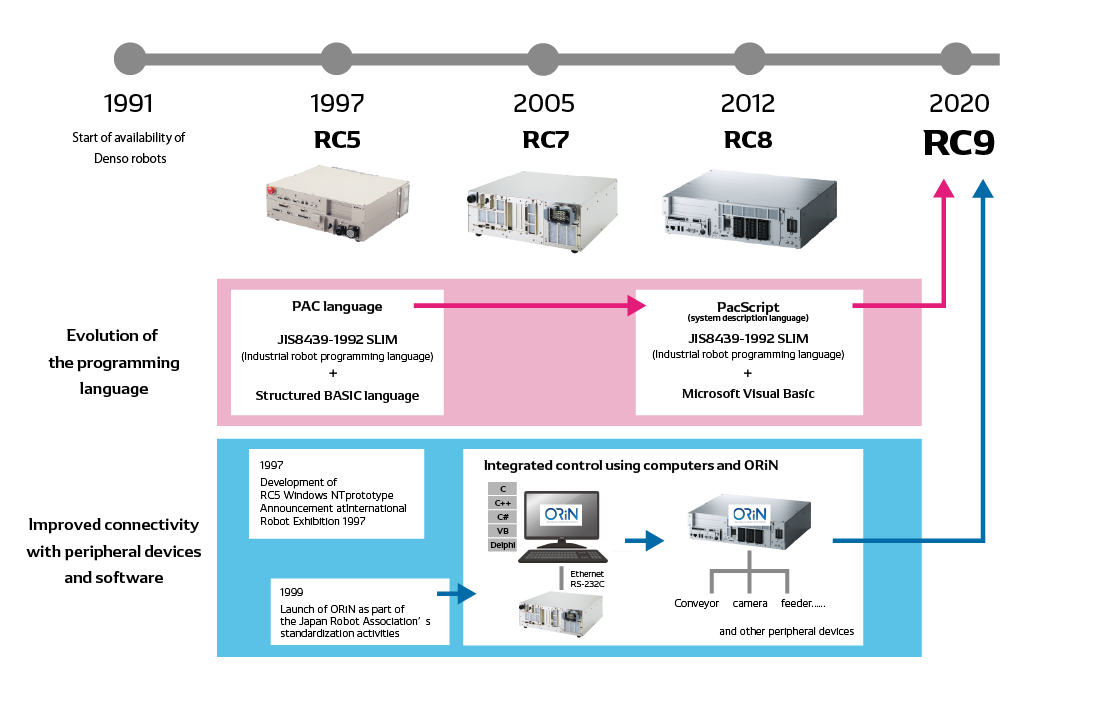

The tradition of openness in Denso robots can be traced back to 1991, just after our robots first became available to outside purchasers. The RC5, which was launched in 1997, used the PAC language, which was based on SLIM, the JIS-defined industrial robot programming language, to which it added practical functions and commands. Subsequent growth in the level of demand for the ability to control robots from computers and to develop applications in languages engineers were already used to, particularly in Europe, prompted the launch in 2005 of the RC7, a robot controller that met these needs. It was at this point that ORiN, a communications interface designed to enable factory automation equipment and applications to communicate in a standardized manner, entered into use. In 2012, the RC8 introduced PacScript, a language that conformed the PAC language to Visual Basic’s grammar so that it could serve as a language for describing systems. The product also supported Visual Basic applications.

Reflecting our goal of enabling the full array of development tasks to be performed using languages that people find easy to use, we believe that a high level of openness is essential in accommodating the complexity of contemporary applications while maintaining the development environment that industry has used in the past.

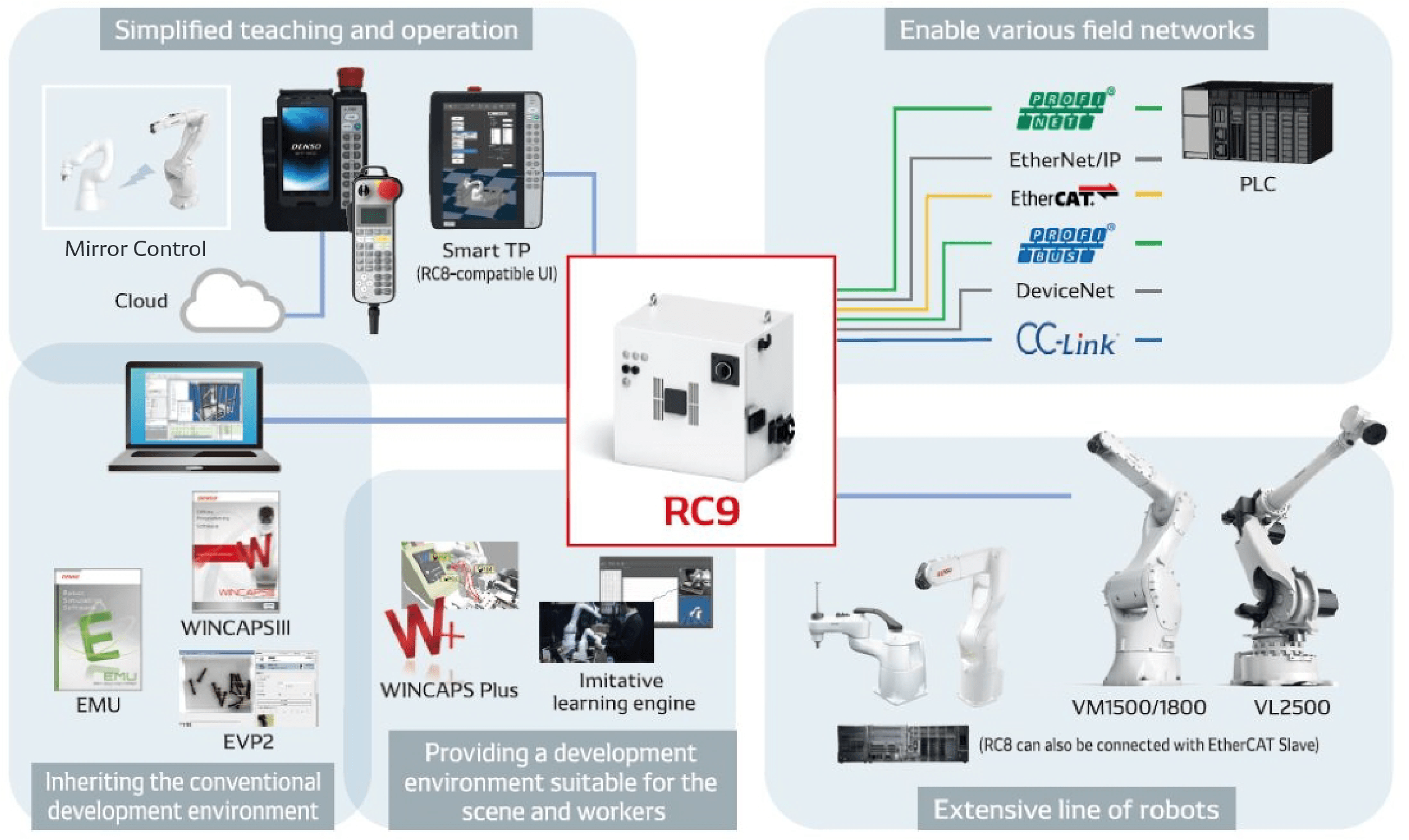

We’ve developed a number of new products so that we can realize Denso’s concept of simplicity while carrying on the openness that we’ve offered to date. The first is the RC9, a new robot controller that was developed to simplify integration of systems that utilize robots. The RC9’s extendibility allows it to be optimized in response to the application at hand, and by providing an open development environment, it accommodates the technologies of customers and system integrators.

We’re also offering the VMB and VLA series of highly portable, long-reach vertical articulated robots so that customers can utilize Denso robots in a broader range of processes. We’ve developed WINCAPS Plus, a suite of applications designed to simplify robot programming by offering a development environment that’s well suited to situations in which robots are used and the workers who use them.

By means of these products, we will offer ease of use to people involved in every stage of robotics, from design and launch to operation and maintenance.

The next segment explains the secret of the powerful development environment provided by the RC9, the lynchpin of system-level integrated control and easy-to-use robotic equipment.

If you have not registered

The services on this member site are available only for registered customers.