Thank you for your visit.This exhibition was held in Tokyo Big Sight.

We are pleased to have been able to welcome so many visitors to our booth.

磨いた技術で、人が輝く、社会をつくる。

More Open, More Easy

2017.11.29 - 12.02 INTERNATIONAL ROBOT EXHIBITION 2017

COBOTTA broadens the range of tasks that can be automated.

-

No.01

3-color pen Factory

Can be easily installed and immediately used for a range of minor factory processes.

-

No.02

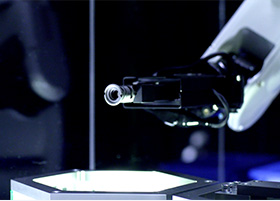

Integrated control system for anticancer agent preparation

COBOTTA is integrated with an ORiN-equipped controller to control a range of devices.

-

No.03

Portable dispensing system

Easy to carry and no need for re-teaching.

-

No.04

Use example in an ink cartridge manufacturing process

You can automate a simple manufacturing process by using COBOTTA in combination with a camera and image processing software.

-

No.05

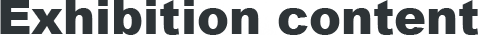

COBOTTA Hackathon best prize winner

Open source software (OSS) can be freely installed to operate COBOTTA.

-

No.06

AI-based multiple robot control technology

AI makes multiple robots work efficiently without the need for programming.

-

No.07

Zone for hands-on experience of simple operation

Robot that can be easily and instantly used anywhere

HSR series that provides excellent basic performance

-

No.08

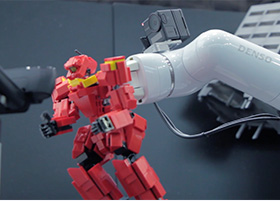

High-speed “pick & place”

IPC integrated control enables high-speed synchronous control of a high-speed linear transporter

-

No.09

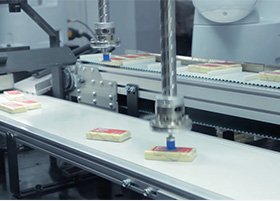

Picking (transfer & alignment) system

Accurate and high-speed picking system contributing to higher line efficiency

-

No.10

Heavy item transportation system

Compact and powerful, and thus suitable for a range of applications

-

No.11

Simple 3D sensor-based inspection and alignment

The 3D sensor recognizes standard goods transported in returnable containers or on a conveyor for accurate picking, thereby automating shipping work.

Evolving robot functions

-

No.12

Harmonized control of multiple units

It enables the establishment of a system to manufacture customized products with high productivity and at low cost.

-

No.13

Dual-arm control

Integrated control of two SCARA robots by one controller

Multi-modal AI robot

-

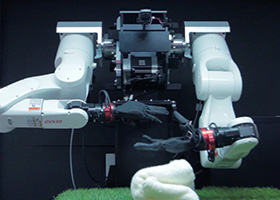

No.14

Deep learning and VR technology-equipped double-arm multi-modal AI robot

The same robot arm performs multiple tasks in the handling of non-standard items.

Protecting the safety of food and medical products

-

No.15

Solution for food-picking robots

Hygienic robot jacket and hand developed for food handling

-

No.16

Compact automatic cell culture system

Small robot system to automate the cell culture process

More Easy

-

No.17

Easy-to-use equipment design support tool

Optimization tool that strongly supports robot motion generation, layout decision and robot selection, which used to be difficult to do at the conceptual design stage

-

No.18

Function to make the robot automatically return to the original position

The combination of 3D CAD data and a low-cost 3D sensor makes the robot automatically return to the original position.

-

No.19

Robot Tools

Robot launch and maintenance support tool for easier maintenance operations

More Open

-

No.20

All Denso robots are ROS compatible.

Compatible with the open source software ROS, which makes the development of robot applications easier

-

No.21

Openness between PLC and Denso robots

Denso robots can be directly controlled using PLC language

-

No.22

CPS(Cyber Pyisical System)

Reduction of lead time in equipment development

-

No.23

IoT Data Server /

IoT Data StudioIoT product that smoothly links FA devices, equipment and factories

FA solution that helps people achieve growth and make the site stronger

-

No.24

D-Depot simplified automatic location package

Automatic location for visualization of management and easy volume change

-

No.25

D-CART transportation package for use in a factory

Easy automation of transportation, including input through to discharge

-

No.26

D-Kit high-speed kitting package

Easy introduction of a super high-speed precision system that aligns components in 3.5 seconds

-

No.27

D-Carry inter-equipment transportation package

Component transportation automated safely and compactly in a manner compatible with manual work done by people

-

No.28

D-View equipment monitoring server

Easy connection for the visualization of a production line/factory, which fosters kaizen at the manufacturing site

-

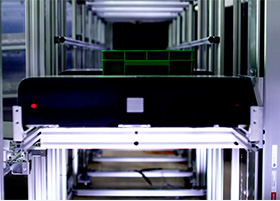

No.29

D-Vision visual inspection package

Easy automation of visual inspections with advanced inspection quality on par with that carried out by an experienced person

-

No.30

D-Cell easy-to-introduce robot cell

Portable and easy-to-use assembly automation cell