DENSO WAVE has been promoting the informatization of equipment by connecting various FA devices for factory equipment to computers since 2005. The Project Department, which had been involved in planning new business in anticipation of IoT since 2014, was renamed the IoT Promotion Division to start afresh in June, 2016. There was the “Innovative Production and Factory” concept behind this move. This concept is to introduce full-scale IoT technology by 2020 in order to connect our 130 factories around the world via networks, thereby improving productivity by 30% from 2015. This was the first time that Denso mapped out the group-wide ambitious goal of network standardization and its numerical target. The IoT Promotion Division started working on the dynamic introduction of IoT in cooperation with Denso’s FIoT Promotion Section of the Innovative Production & Factory Promotion Division.

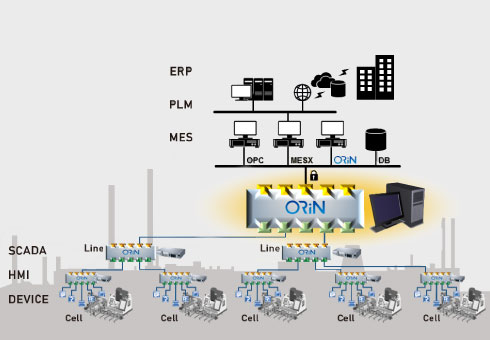

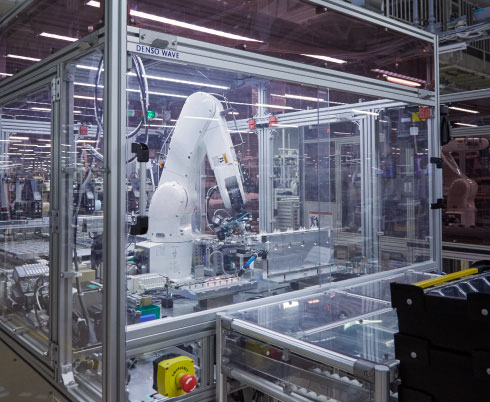

Factory data, including the operation rate, was stored by equipment separately before. This was the “one-piece” system dependent on FA devices for each equipment. Systems that cannot be deployed horizontally or advanced end up increasing operators’ workloads. The manufacturing sites urgently needed a smarter system to improve efficiency.If factory equipment is uniformly connected, a system can be introduced that collects and analyzes equipment data to improve the line operation rate. Furthermore, if a system is developed that visualizes equipment data for the factory as a whole, it is possible to assess the situation of the entire line and thoroughly control defective products to prevent them from outflowing into downstream processes, thereby improving the quality of products. Like these, multiple benefits can be generated. This means that a “general-purpose” system was required that could be used in and applied to any factory.

The first thing to do was to uniformly connect various FA devices and build factory networks.

General Manager Tomoyuki Nanami,

Planning Department, IoT Promotion Division

IoT is the concept of connecting goods and things with the Internet. To realize the introduction of IoT, all FA devices need to be connected. However, in the FA industry, because many companies were hesitant to build networks (introduce IT) for equipment, the industry was overtaken by other industries. In addition, each FA device has its own communications specifications and a long lifecycle, so some devices cannot be connected or do not have communications specifications. This situation was a problem to members of the IoT Promotion Division. To connect all FA devices, it was necessary to adopt specifications that could function as a hub. The hub specifications needed to cover not only the communications specifications for each device but also various standard specifications.

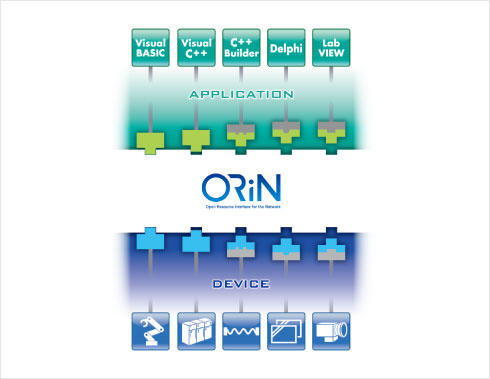

Building factory networks and introducing systems for the informatization of factories as a whole, thereby improving productivity ― the ideal solution to this essentially required middleware that could efficiently collect the information of various FA devices. Based on the standard middleware ORiN specifications for factory IT systems, which was specified by the ORiN Council, DENSO WAVE took the initiative in developing ORiN with the support of NEDO and the Japan Robot Association. The ORiN Council was established as part of the standardization activity led by the Japan Robot Association. When a computer is connected via an upper application software program to FA devices of robots, etc., this ORiN platform unifies each maker’s communications specifications to convert them into a uniform method. This eliminates the needs for developing individual methods for different FA device specifications, allowing smarter development.

In 2006, DENSO WAVE commercialized the software tool kit ORiN2 SDK (software development kit) for developing application programs and providers based on the ORiN2 specifications (the advanced version of ORiN1). Using this software program allows the connection of computers via common methods to different FA devices (robots, PLCs, and NC machine tools, etc. produced by various makers) and the simple development of upper application software programs with general-purpose languages (C#, C++, VBA, JAVA etc.). Members of the IoT Promotion Division say with assurance: “The originality of each manufacturing site is to collect and analyze data in production processes to improve productivity. The commercialization of the ORiN2 SDK allows the simple development of upper application software programs that help manufacturing sites make improvements, thereby significantly contributing to systemization.

Assistant Manager Munetoshi Yoneyama,

Planning Department, IoT Promotion Division

The IoT Promotion Division has a new vision of releasing a software program in 2018, which utilizes ORiN to accumulate the know-how of FA device connection methods while collecting data of factory equipment. In the early development stage, members struggled to break the stereotype of FA devices being isolated from computers, and worked hard to disseminate a concept of building networks to connect FA devices to computers. Now these members have accumulated development know-how and acquired confidence, which led them to their new vision. They will not stop with the development of products, and see the data collection software just as a milestone and will keep moving forward. The IoT Promotion Division continues to provide products and support services for the introduction of IoT. Eventually, their enthusiasm will lead to a driving force not only for the introduction of IoT in the automobile industry, but also for the invigoration of the manufacturing industry in the technological superpower Japan.

If you have not registered

The services on this member site are available only for registered customers.