This exhibition was held in Tokyo Big Sight.

We are pleased to have been able to welcome so many visitors to our booth.

We, as your partner for creating robust worksites, will offer total solutions for your factory that are created through manufacturing expertise accumulated in our own factories with the theme of “LEAN for Your Factory.” We pursue the enhancement of productivity and user-friendliness, and will exhibit new products and new functions of continuously evolving Denso robots, solutions for reducing lead time from process design to equipment introduction and for providing support for maintenance and improvement work after equipment introduction, and many more.

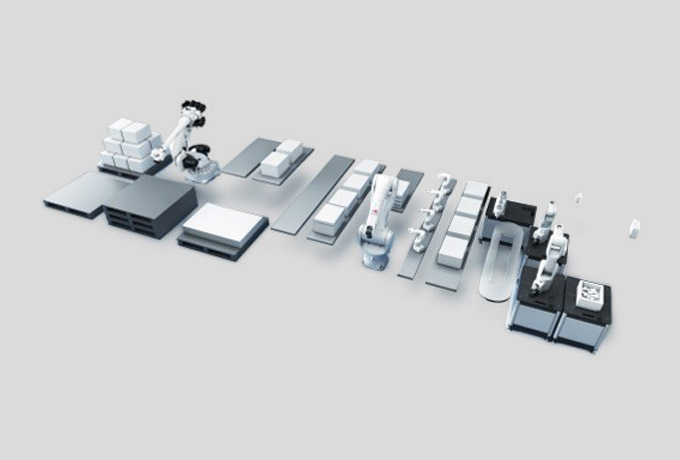

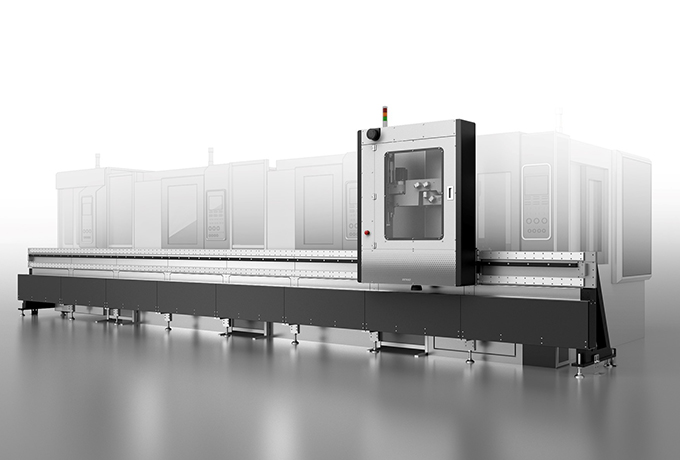

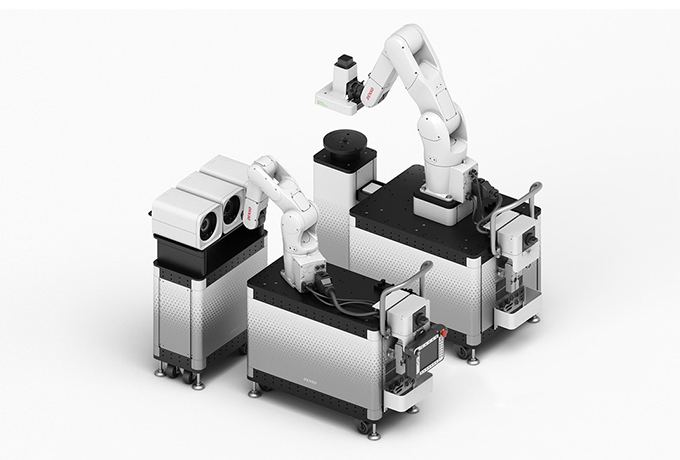

Automation solution

RC9 integration production line

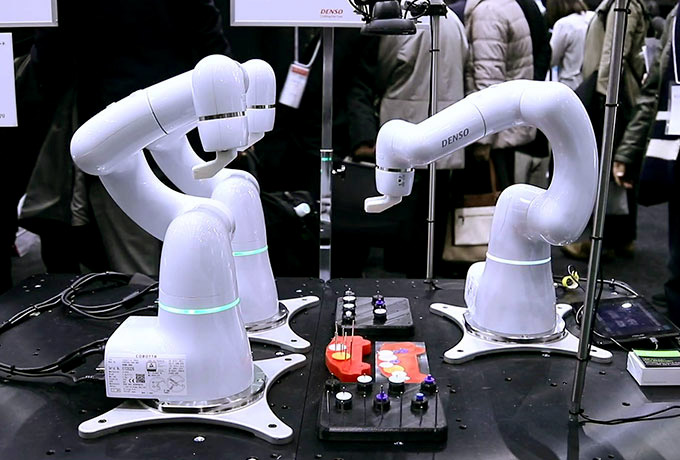

We will present a production line that is controlled in an integrated manner with the new robot controller RC9, which is characterized by openness that offers a development environment familiar to field workers as well as real-time capabilities that maximize robot performance. “VM Series” and “VL Series,” a new lineup of DENSO Robotics, are used to demonstrate packing and palletizing of COBOTTA.

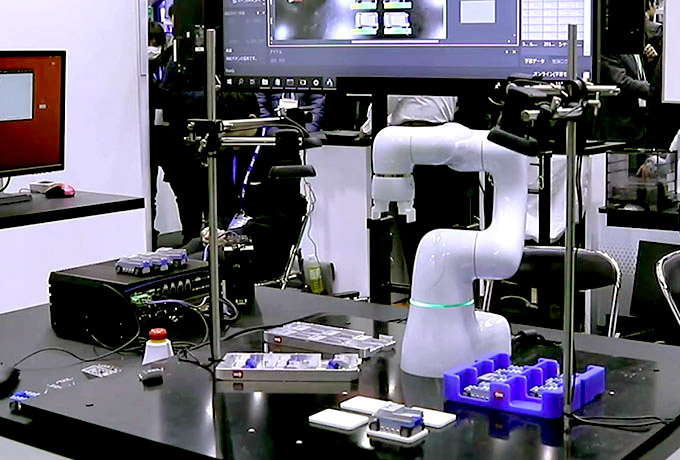

COBOTTA® expanding the areas

of automation

We will exhibit solutions in four fields including “Industry,” “Laboratory,” “Academic” and “Office” by COBOTTA, our first collaborative robot with humans that was launched to the market last year. Applications we have developed in cooperation with our partner companies to automate highly challenging work in a factory and office work will be exhibited.

Compactly automating multiple

processes

We will demonstrate how to automate multiple processes, such as assembly and inspection, in a space-saving manner. In addition, we will exhibit the compact SCARA robot “LPH-040,” which is optimal as the entry model and will be launched in Japan in January next year.

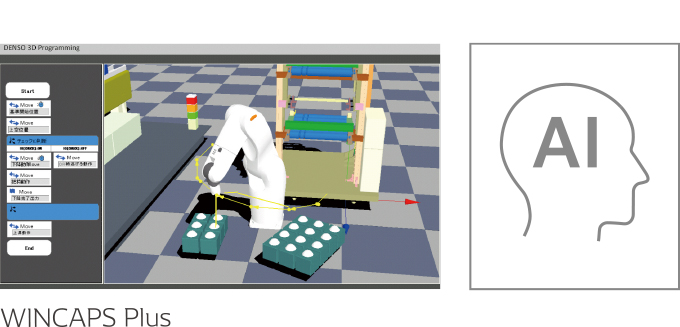

Experience on “easy-to-use”

products

We will introduce you to software and devices that enable an easy-to-use development environment tailored to each customer. Applications that are combined with multi modal AI to make programming easier, the functionality expansion software “WINCAPS Plus” that reduces development man-hours and a teaching device that can be chosen according to the development environment will be exhibited.

Process streamlining solution

We will exhibit solutions that pursue the enhancement of productivity with an eye to every phase from before equipment introduction to operation after introduction. We will introduce you to D-Vision, an appearance inspection solution, D-Depot, an inventory reduction solution, D-Carry, an inter-facility transportation package and D-Cell, a general-purpose mount package for industrial robots.

IoT solution

We will exhibit an IoT Data Server with the middleware ORiN (which supports more than 200 types of providers) implemented as standard. Our “Useful IoT” initiatives where connections with a wide range of equipments and applications can be easily established and setups can be done without creating complex programs will be introduced to you by using case studies.

Factory security solution

We will introduce you to a Factory Security Diagnosis service where a security solution optimized for your worksite is offered. In addition, we will exhibit solutions for protecting “production information,” “product quality” and “worker safety.”

For the detailed informationHuman development solution

We will introduce you to our initiatives to develop “human who create a robust workplace” based on a Lean AutomationR philosophy we have developed for manufacturing.

For the detailed informationAutomation solutionRC9 integration production line

RC9

integration production line

Initially undefined to offer freedom to define according to needs Introducing the new robot controller "RC9"

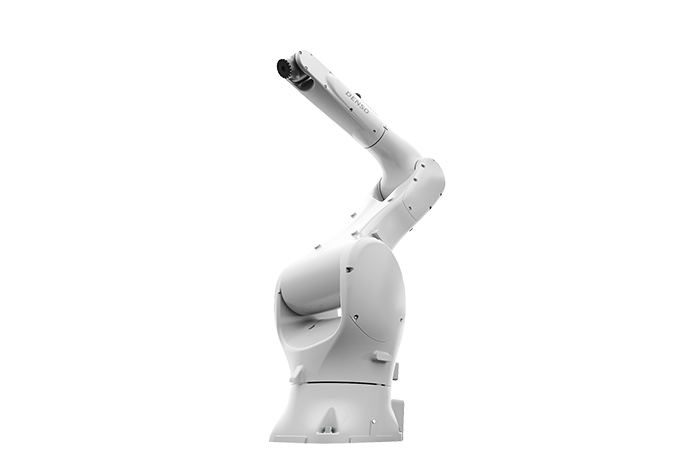

Overview Panel (PDF)New vertical articulated robot

"VM" series

Optimal for transport and palletizing tasks, freeing workers from work handling heavy objects

Overview Panel (PDF)New vertical articulated robot

"VL" series

The greatest portable mass and longest arm reach in the DENSO robot history

Overview Panel (PDF)Automation solutionCOBOTTA® expanding the areas of automation

AI generates flow control for cooperative work conducted

by multiple units

Reduces development steps for conditional branch programming.Corresponds to changes in production quantity by dividing labor with robots!

Overview Panel (PDF)Labelling bottles and tubes of various

types and shapes

Instant and easy HMI correspondence to product changes

Overview Panel (PDF)Automation of harness assembly,

which is a highly complex operation

Finally, automation for extremely complex harness assembly

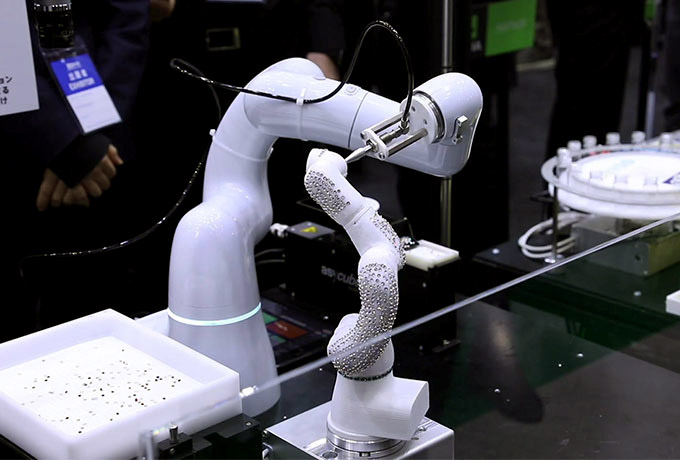

Overview Panel (PDF)Alignment of transparent and reflective materials with application of AI vision

Continuous picking of bottles of multiple shapes with AI that does not need training

Overview Panel (PDF)Assembly of crystal parts by an accurate, flexible-vision picking module

±0.05mm accuracy

Leave precise craftsmanship to COBOTTA

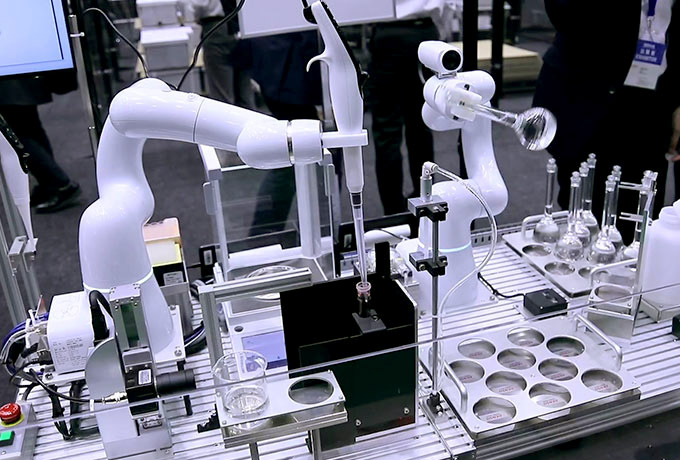

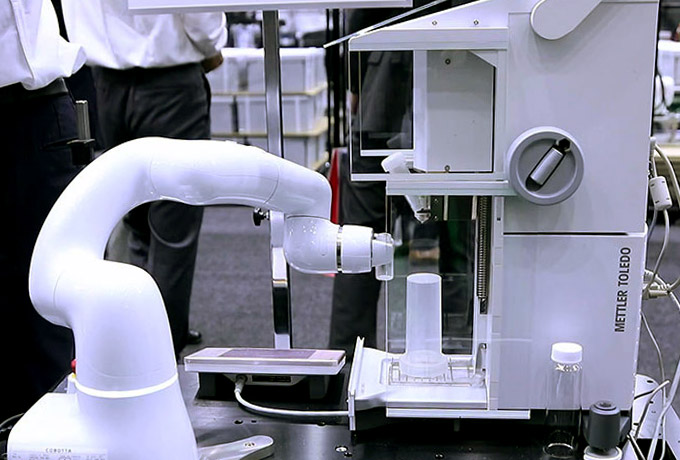

Automation of fixed volume and

mixing tasks with material analysis

Table-top-sized automation of analysis tasks and traceability management

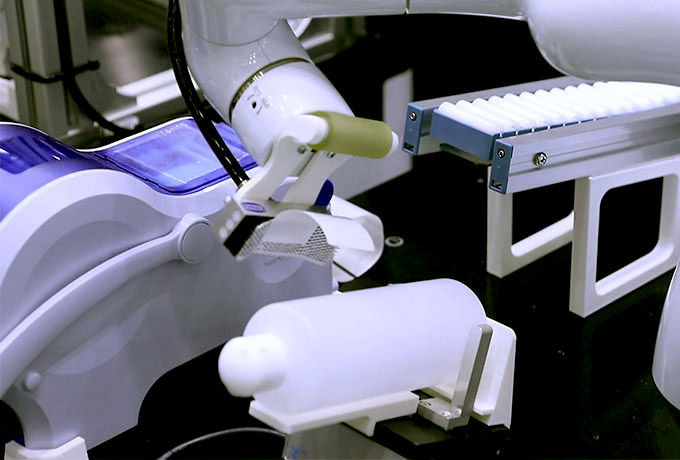

Overview Panel (PDF)Automation of vial filling/emptying to

automatic dispensers

Easy automation of dispensing apparatus setup tasks

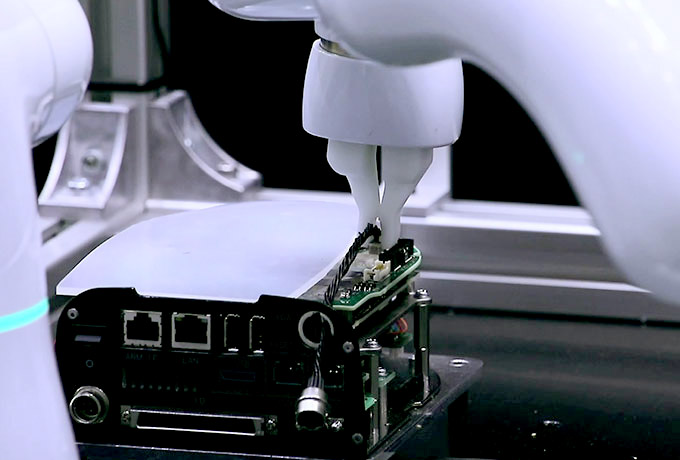

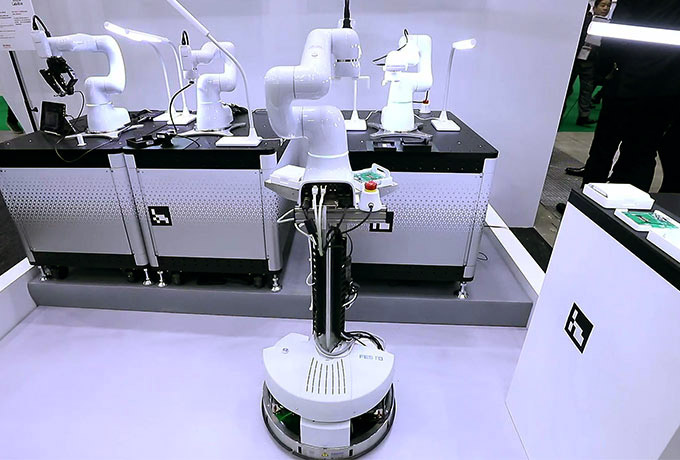

Overview Panel (PDF)Interface module assembly

with COBOTTA and mobile robots

Programming within a free development environment with languages used in the classroom such as ROS and LabVIEW

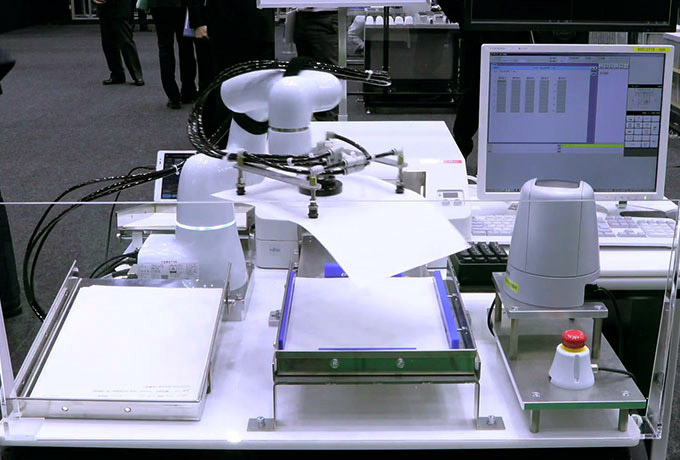

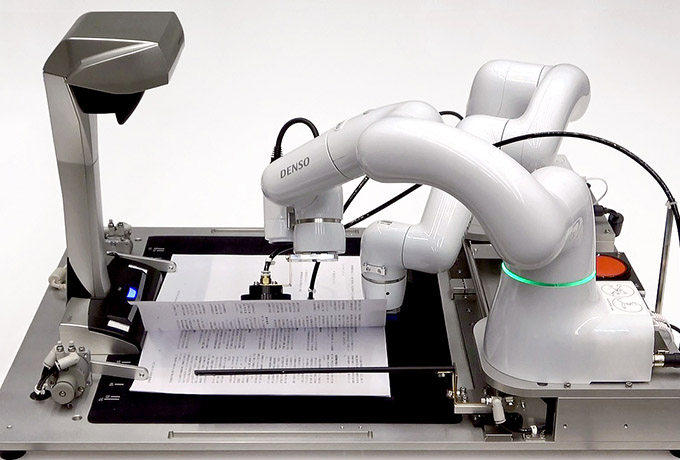

Overview Panel (PDF)[Case example of Mitsubishi UFJ Trust

and Banking Corporation]Automation of paper feeding and ejection

for printers

Promotes workstyle reform Reduction of approximately 50% of fixed print work man-hours

Overview Panel (PDF)[Joint development by Hitachi Capital, Hitachi Systems,

and Denso Wave]RPA&COBOTTA Automation support

for offices

[Joint development by Hitachi Capital, Hitachi Systems, and Denso Wave]

RPA&COBOTTA Automation support for offices

Experience easy COBOTTA operation

A simple GUI which allows robot beginners to automate tasks in 10 minutes

Overview Panel (PDF)Automation solutionCompactly automating multiple processes

Handy scanner assembly conducted by

two arms and multiple-digit hands

Automation of human tasks as-is with two arms and multiple-fingered hands A compact, versatile robot that also conducts inspections

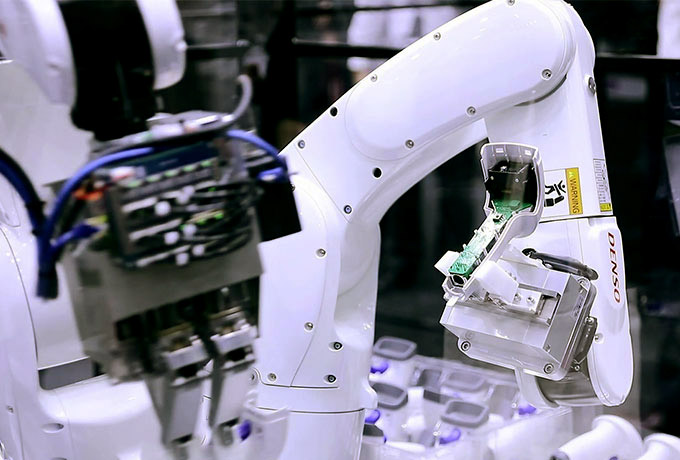

Overview Panel (PDF)Robot controller assembly and

external inspection

An external inspection cell added on to swift, highly-accurate and transportable assembly cellFlexible operations become possible

Overview Panel (PDF)Entry model SCARA robot "LPH"

Prompt delivery in two weeks! A reasonably-priced, simple entry model SCARA robot

Overview Panel (PDF)Experience on “easy-to-use” products

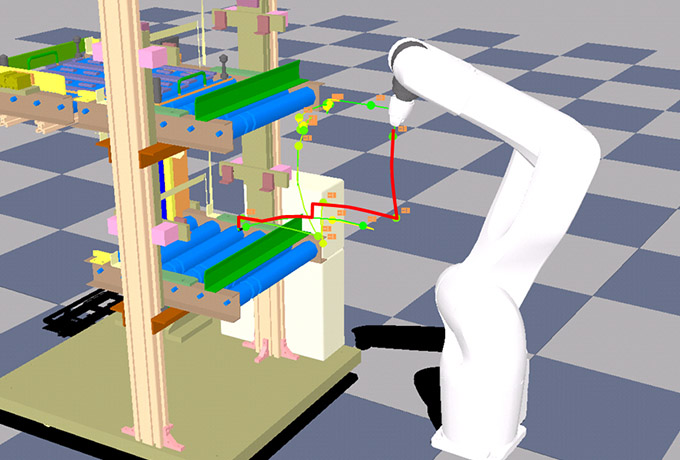

WINCAPS Plus

"Optimal Motion Planner"

As good as experienced designers! Allows anyone to achieve optimal cycle times

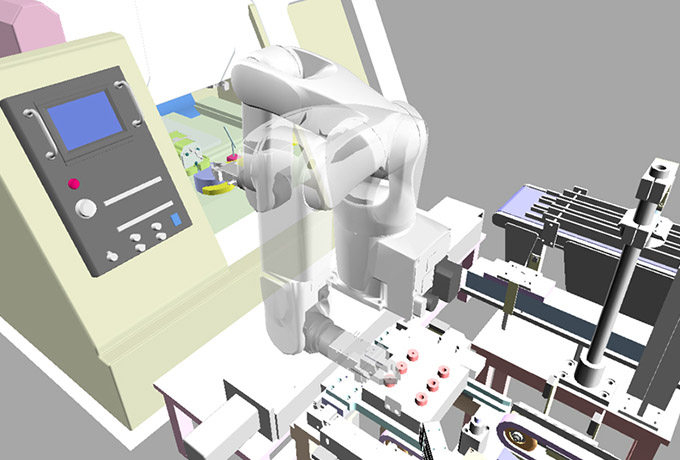

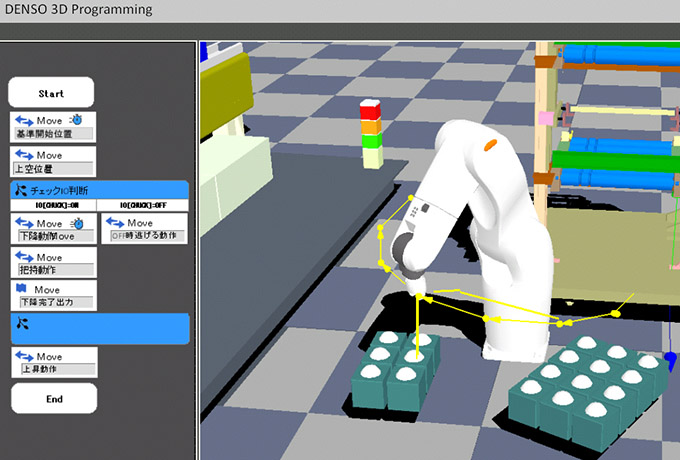

Overview Panel (PDF)WINCAPS Plus

"3D Visual Programming"

Allows for more intuitive robot operation programming with 3D

Overview Panel (PDF)WINCAPS Plus

"Home Position Guidance"

No programming necessary! Automatic generation of return to origin operations

Overview Panel (PDF)New Teaching Systems

“Smart TP”“BHT-1800”

Operation devices selected according to customer environment

Overview Panel (PDF)[AI learning experience]AI generation of flow control

(conditional branch), the reason

for programming complexity

[AI commercialization]Taskflow generator Dramatically reduces conditional branch programming man-hours

Overview Panel (PDF)[AI learning experience]AI learns human actions that cannot be

put into words,

and imitates them with a robot arm

[AI commercialization] Imitation movement learning Atomation of "getting the hang of" activities which cannot be put into words

Overview Panel (PDF)AI generates optimal parameters for

force sensors according to each

application

[AI commercialization] Realtime optimization of parameter configurations for compliance control

Overview Panel (PDF)Process streamlining solution

Inventory reduction solution D-Depot

with convertible, transparent and

automated storage

An inventory reduction solution that assists on-site diagnosis to operation

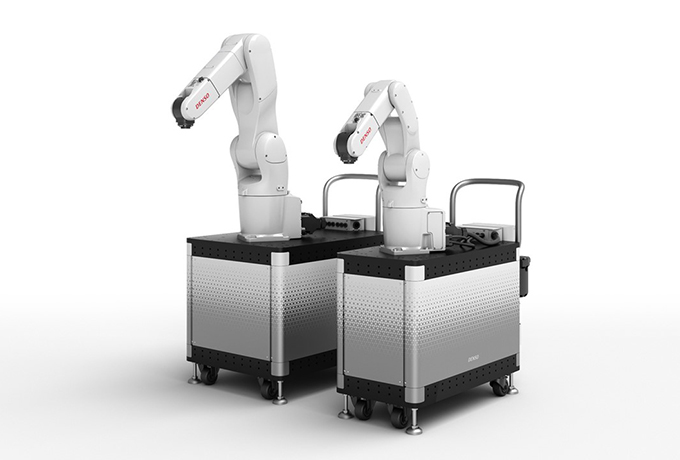

Overview Panel (PDF)D-Cell general-purpose frame package

for industrial robots

A 30% reduction of equipment launch man-hours! A general-purpose robot frame that supports changes in future processes

Overview Panel (PDF)D-Carry facility-to-facility transportation package Slim and able to coexist with

workers

Shorten design/installation lead times by 75%! A slim, facility-to-facility transportation package that can coexist with workers

Overview Panel (PDF)D-Vision external inspection solution with AI and intuitive UI application

Three steps in 30 minutes. An external inspection solution that allows for easy launch with one worker

Overview Panel (PDF)IoT solution

IoT solution

Formidable on-site connectivity IoT that starts small and grows large

Overview Panel (PDF)Factory security solution

Human development solution

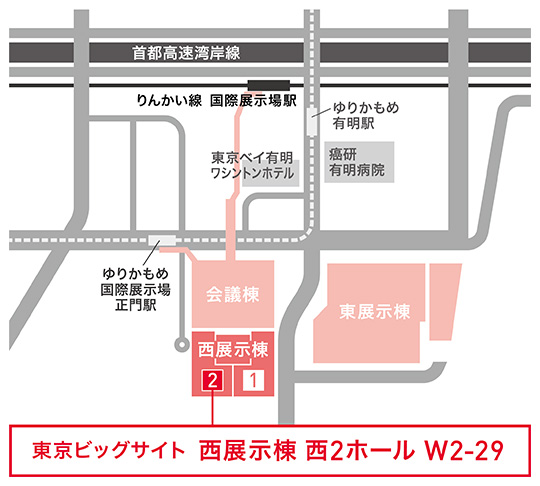

◆DATE:

Dec.18 Wed.- 21 Sat. 2019 10:00-17:00

◆Venue:

Tokyo Big Sight | Aomi Halls, West Halls,

South Halls

◆Booth

No.:West Hall2 W2-29

◆WEB:

https://biz.nikkan.co.jp/eve/irex/english/

◆Admission:

JPY 1,000

(free admission to people who have preregistered or

who hold invitations, or are under 16 years of age)

We will send you information on new products and exhibition.

Contact UsIf you have not registered

The services on this member site are available only for registered customers.