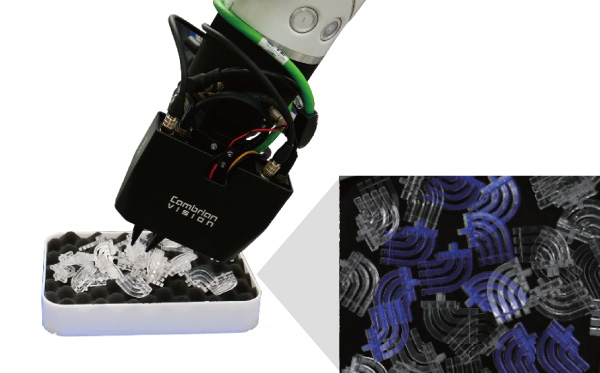

●Conventional 3D vision is not good at recognizing small, transparent, or glossy workpieces.

●Conventional 3D vision is easily affected by ambient light, and changes in ambient light conditions sometimes make highly accurate recognition difficult.

A stereo camera enables recognition of the target object without auxiliary lighting such as structured light or infrared to provide high stability under various natural light conditions, and the recognition of transparent or glossy workpieces.

Enables high-precision recognition of workpieces smaller than 1 mm for picking of extremely small workpieces (1 mm x 1 mm)

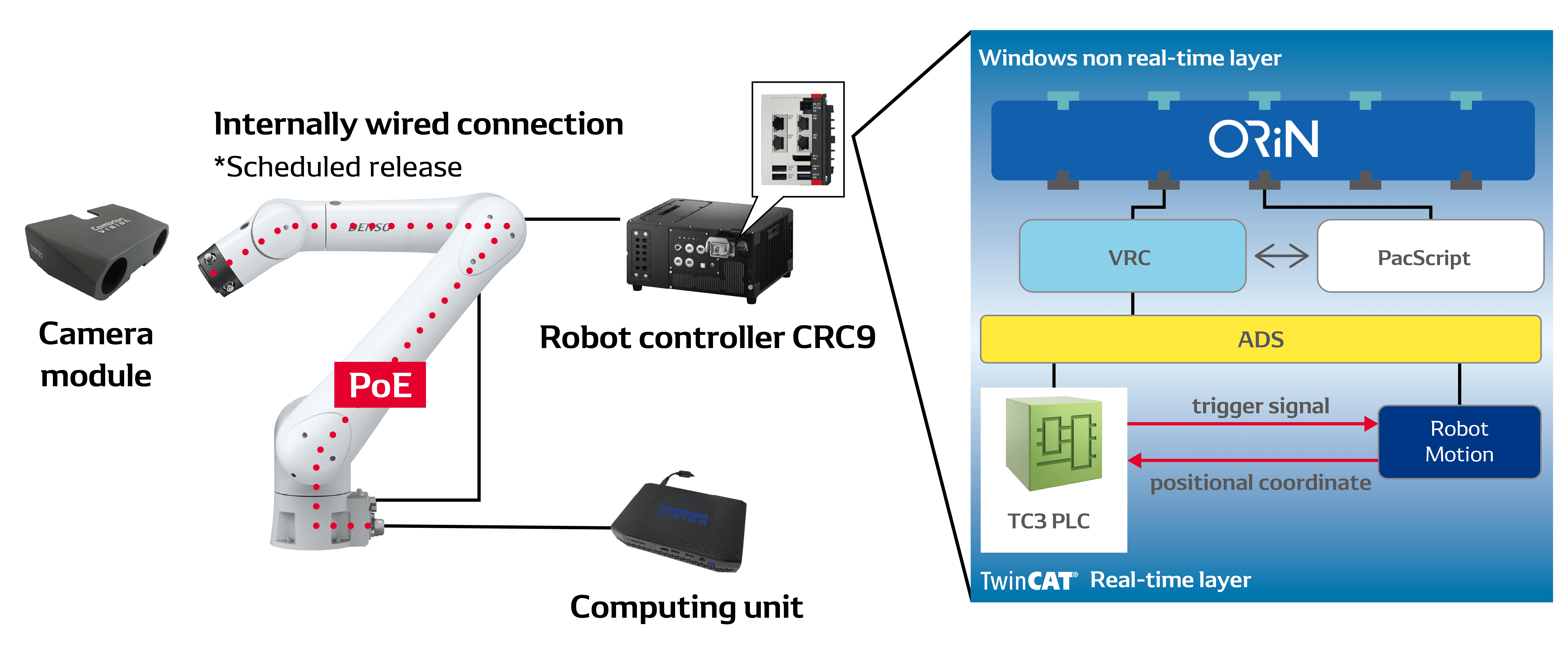

Workpiece image processing can be achieved in approximately 0.3 seconds after imaging

By incorporating the function inside the TwinCAT of the RC9, accurate positional information can be understood while the robot arm is operating in conjunction with the shutter signal, and imaging is possible without stopping the robot. This reduces the cycle time, as stopping time is not required.

If you have not registered

The services on this member site are available only for registered customers.