●Simple tasks like transporting parts took workers’ time, leading to a labor shortage.

●Manufacturers using multi-model, small-lot production had to recognize many part models with a camera, increasing the number of man-hours spent on compiling master databases (CAD) and other data.

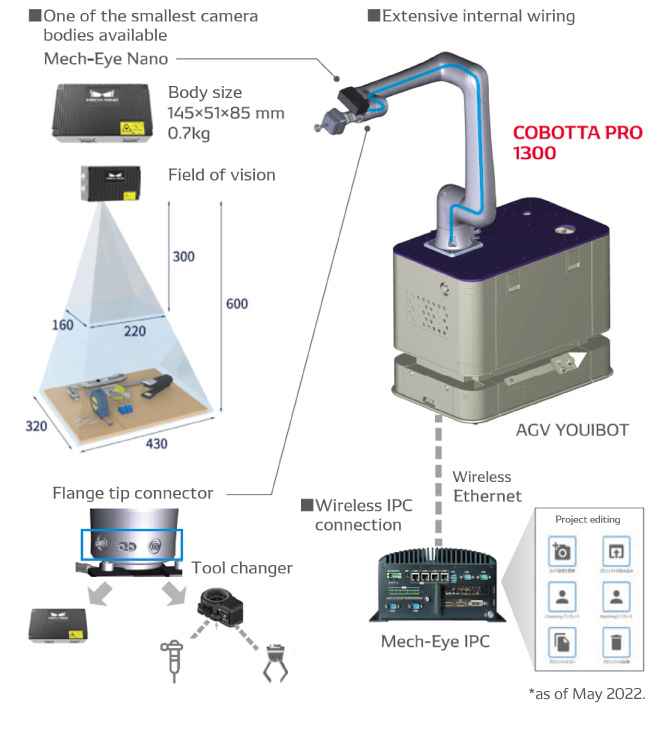

The CRC9 implements integrated control of the COBOTTA PRO and peripheral equipment like hands and vision devices. The Mech-Eye 3D vision system’s deep learning function is used to recognize the locations of numerous parts. The plan identifies and picks pieces by scanning QR codes applied to shelves.

In addition, all hand wiring has been routed within the robot to realize a solution with less exposed wiring.

The COBOTTA PRO supports the CRC9 robot controller. This controller provides integrated control of the robot arm and peripheral equipment like 3D vision devices and hands.

Mech-Eye is a line of 10 high-precision 3D vision devices. By combining conventional rule-based recognition with deep learning functionality, Mech-Eye implements high-precision object recognition.There’s no need for models (CAD data). A specialized GUI developed by Denso Wave improves ease of use and work efficiency.

Mech-Eye is a line of 10 high-precision 3D vision devices. These products can be used in applications such as assembly, positioning, sorting, transport, and palletizing. There’s no need for models (CAD data). A specialized GUI developed by Denso Wave improves ease of use and work efficiency.

If you have not registered

The services on this member site are available only for registered customers.