The compact and slim body has outstanding high power and speed.

Maximum arm reach|653 / 854mm

Maximum payload|7kg

Cycle time|0.49 / 0.59 sec

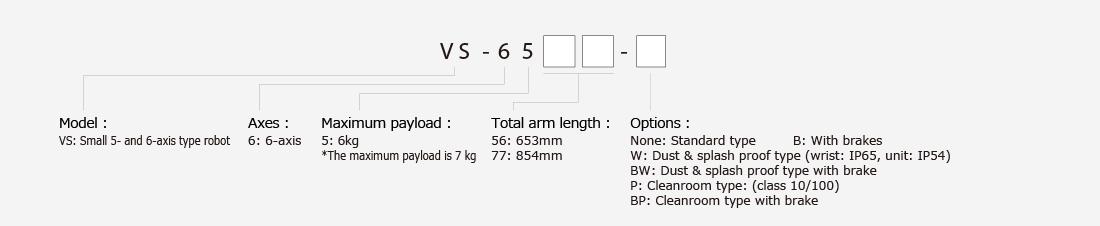

With a maximum payload of 7 kg (wrist orientation: ±45 degrees max. with respect to the downward vertical direction)*1, the VS-6556 and the VP-6577 are very powerful for their small size, allowing greater flexibility of hand design.

With a small arm width of 110 mm, the VS-6556 and the VP-6577 can reduce interference with other facilities.

The footprint is only 200 mm x 200 mm. The entire body fits into an area of two standard postcards, helping size reduction of facilities.

The dust-proof, mist-proof type, which can be used under severe use conditions, and the clean type, which is perfect for automatization of clean rooms.

| Maximum arm reach | Brake |

Standard type |

Dust- & splash-proof type [wrist:IP65、 Robot Unit:Equivalent to IP54] |

Clean room type(*2) [Clean level: class10(0.1μm) class100(0.3μm)] |

|---|---|---|---|---|

| 650mm |

Standard type:2・3・4-axisWith Brakes |

VS-6556 | VS-6556-W | VS-6556-P |

| 850mm | VS-6577 | VS-6577-W | VS-6577-P | |

| 650mm | Expansion: Brakes for all joints (not contained in 1-axis) |

VS-6556-B | VS-6556-BW | VS-6556-BP |

| 850mm | VS-6577-B | VS-6577-BW | VS-6577-BP |

| Item | Standard type | Standard type / With brakes | |||

|---|---|---|---|---|---|

| Model name of robot unit | VS-6556 | VS-6577 | VS-6556-B | VS-6577-B | |

| Axes | 6 | ||||

| Overall arm length | 270(first arm)+ 295(second arm)=565mm |

365(first arm)+ 405(second arm)=770mm |

270(first arm)+ 295(second arm)=565mm |

365(first arm)+ 405(second arm)=770mm |

|

| Arm offset | J1(swing):75mm J3(front arm):90mm | ||||

| Maximum motion area | R=733mm(end-effector mounting face) R=653mm (Point P: J4, J5, J6 center) |

R=934mm(end-effector mounting face) R=854mm (Point P: J4, J5, J6 center) |

R=733mm(end-effector mounting face) R=653mm (Point P: J4, J5, J6 center) |

R=934mm(end-effector mounting face) R=854mm (Point P: J4, J5, J6 center) |

|

| Motion range | J1:±170°, J2:+135°, -100°, J3:+166°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+169°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+166°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+169°, -119°, J4:±190°, J5:±120°, J6:±360° |

|

| Maximum payload | 7kg(Within a downward wrist angle of movement of ±45°) (※4) | ||||

| Maximum composite speed | 8200mm/s (at the center of an end-effector mounting face) |

7600mm/s (at the center of an end-effector mounting face) |

8200mm/s (at the center of an end-effector mounting face) |

7600mm/s (at the center of an end-effector mounting face) |

|

| Cycle time(※1) | Approx. 0.4(sec) | Approx. 0.5(sec) | Approx. 0.4(sec) | Approx. 0.5(sec) | |

| Position repeatability(※2) | In each of X, Y and Z directions:±0.02mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.03mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.02mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.03mm (at the center of an end-effector mounting face) |

|

| Maximum allowable inertia moment | Around J4 and J5:0.41kgm2 Around J6:0.063kgm2 (7kg payload) | ||||

| Position detection | Absolute encoder | ||||

| Drive motor and brake | AC servomotors for all joints, Brakes for joints J2 to J4 | AC servomotors for all joints, Brakes for joints J2 to J6 | |||

| Brake releasing | Enter a brake release command with the teach pendant or mini-pendant. | ||||

| User air piping(※3) | 7 systems(φ4x6、φ6x1) 3 solenoid valves (2-position, double solenoid) contained. |

||||

| User signal line | 10(for proximity sensor signals, etc.) | ||||

| Air source | Operating pressure | 1.0×105Pa - 3.9×105Pa | |||

| Maximum allowable pressure | 4.9×105Pa | ||||

| Degree of protection | IP40 | ||||

| Airborne noise | 80dB or less(A-weighted equivalent continuous sound pressure level) | ||||

| Weight | Approx. 35kg (77lb) | Approx. 36kg (80lb) | Approx. 35kg (77lb) | Approx. 36kg (80lb) | |

| Item | Dust- & splash- proof type | Dust- & splash- proof type / With brakes | |||

|---|---|---|---|---|---|

| Model name of robot unit | VS-6556-W | VS-6577-W | VS-6556-BW | VS-6577-BW | |

| Axes | 6 | ||||

| Overall arm length | 270(first arm)+ 295(second arm)=565mm |

365(first arm)+ 405(second arm)=770mm |

270(first arm)+ 295(second arm)=565mm |

365(first arm)+ 405(second arm)=770mm |

|

| Arm offset | J1(swing):75mm J3(front arm):90mm | ||||

| Maximum motion area | R=733mm(end-effector mounting face) R=653mm (Point P: J4, J5, J6 center) |

R=934mm(end-effector mounting face) R=854mm (Point P: J4, J5, J6 center) |

R=733mm(end-effector mounting face) R=653mm (Point P: J4, J5, J6 center) |

R=934mm(end-effector mounting face) R=854mm (Point P: J4, J5, J6 center) |

|

| Motion range | J1:±170°, J2:+135°, -100°, J3:+166°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+169°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+166°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+169°, -119°, J4:±190°, J5:±120°, J6:±360° |

|

| Maximum payload | 7kg(Within a downward wrist angle of movement of ±45°) (※4) | ||||

| Maximum composite speed | 8200mm/s (at the center of an end-effector mounting face) |

7600mm/s (at the center of an end-effector mounting face) |

8200mm/s (at the center of an end-effector mounting face) |

7600mm/s (at the center of an end-effector mounting face) |

|

| Cycle time(※1) | Approx. 0.4(sec) | Approx. 0.5(sec) | Approx. 0.4(sec) | Approx. 0.5(sec) | |

| Position repeatability(※2) | In each of X, Y and Z directions:±0.02mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.03mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.02mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.03mm (at the center of an end-effector mounting face) |

|

| Maximum allowable inertia moment | Around J4 and J5:0.413kgm2 Around J6:0.063kgm2 (7kg payload) | ||||

| Position detection | Absolute encoder | ||||

| Drive motor and brake | AC servomotors for all joints, Brakes for joints J2 to J4 | AC servomotors for all joints, Brakes for joints J2 to J6 | |||

| Brake releasing | Enter a brake release command with the teach pendant or mini-pendant. | ||||

| User air piping(※3) | 7 systems(φ4x6,φ6x1)Solenoid Valve(2Position, Double Solenoids)×3 | ||||

| User signal line | 10(for proximity sensor signals, etc.) | ||||

| Air source | Operating pressure | 1.0×105Pa - 3.9×105Pa | |||

| Maximum allowable pressure | 4.9×105Pa | ||||

| Degree of protection | IP54(Wrist:IP65) | ||||

| Airborne noise | 80dB or less(A-weighted equivalent continuous sound pressure level) | ||||

| Weight | Approx. 35kg(Approx. 77lb) | Approx. 36kg(Approx. 80lb) | Approx. 35kg(Approx. 77lb) | Approx. 36kg(Approx. 80lb) | |

| Item | Clean room type | Clean room type / With brakes | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Model name of robot unit | VS-6556 -P10 |

VS-6556 -P100 |

VS-6577 -P10 |

VS-6577 -P100 |

VS-6556 -BP10 |

VS-6556 -BP100 |

VS-6577 -BP10 |

VS-6577 -BP100 |

|

| Axes | 6 | ||||||||

| Overall arm length | 270(first arm) +295(second arm)=565mm |

365(first arm) +405(second arm)=770mm |

270(first arm) +295(second arm)=565mm |

365(first arm) +405(second arm)=770mm |

|||||

| Arm offset | J1(swing):75mm J3(front arm):90mm | ||||||||

| Maximum motion area | R=733mm(end-effector mounting face) R=653mm (Point P: J4, J5, J6 center) |

R=934mm(end-effector mounting face) R=854mm (Point P: J4, J5, J6 center) |

R=733mm(end-effector mounting face) R=653mm (Point P: J4, J5, J6 center) |

R=934mm(end-effector mounting face) R=854mm (Point P: J4, J5, J6 center) |

|||||

| Motion range | J1:±170°, J2:+135°, -100°, J3:+166°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+169°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+166°, -119°, J4:±190°, J5:±120°, J6:±360° |

J1:±170°, J2:+135°, -100°, J3:+169°, -119°, J4:±190°, J5:±120°, J6:±360° |

|||||

| Maximum payload | 7kg(Within a downward wrist angle of movement of ±45°)(※4) | ||||||||

| Maximum composite speed | 8200mm/s (at the center of an end-effector mounting face) |

7600mm/s (at the center of an end-effector mounting face) |

8200mm/s (at the center of an end-effector mounting face) |

7600mm/s (at the center of an end-effector mounting face) |

|||||

| Cycle time(※1) | Approx. 0.4(sec) | Approx. 0.5(sec) | Approx. 0.4(sec) | Approx. 0.5(sec) | |||||

| Position repeatability(※2) | In each of X, Y and Z directions:±0.02mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.03mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.02mm (at the center of an end-effector mounting face) |

In each of X, Y and Z directions:±0.03mm (at the center of an end-effector mounting face) |

|||||

| Maximum allowable inertia moment | Around J4 and J5:0.413kgm2 Around J6:0.063kgm2 (7kg payload) | ||||||||

| Position detection | Absolute encoder | ||||||||

| Drive motor and brake | AC servomotors for all joints, Brakes for joints J2 to J4 | AC servomotors for all joints, Brakes for joints J2 to J6 | |||||||

| User air piping(※3) | 6 systems(φ4×6) Solenoid Valve(2Position, Double Solenoids)×3 | ||||||||

| User signal line | 10(for proximity sensor signals, etc.) | ||||||||

| Air source | Operating pressure | 1.0×105Pa - 3.9×105Pa | |||||||

| Maximum allowable pressure | 4.9×105Pa | ||||||||

| Degree of protection | Class 10(0.1μ) | Class 100(0.3μ) | Class 10(0.1μ) | Class 100(0.3μ) | Class 10(0.1μ) | Class 100(0.3μ) | Class 10(0.1μ) | Class 100(0.3μ) | |

| Airborne noise | 80dB or less(A-weighted equivalent continuous sound pressure level) | ||||||||

| Weight | Approx. 35kg (Approx. 77lb) | Approx. 36kg (Approx. 80lb) | Approx. 35kg (Approx. 77lb) | Approx. 36kg (Approx. 80lb) | |||||

| Group | Item | Q'ty |

|---|---|---|

| Robot & Accessories | Robot unit | 1 |

| Motor & encoder cable (option) | 1 | |

| Sheet of direction indicator labels | 1 | |

| Connector set for hand control signals (for CN20 and CN21) | 1set | |

| Dowel pins (internally threaded positioning pin and diamond-shaped pin) | 1set | |

| Controller & Accessories | Robot controller | 1 |

| Power cable (5 m) | 1 | |

| Pendantless connector (Dummy connector) | 1 | |

| Cable clamp | 1 | |

| Software etc | WINCAPS III trial version installer disc | 1 |

| Manuals ("Manual Pack disc" and "Safety Precautions") | 1set | |

| Warning label | 1 |

| Type | Item | ||

|---|---|---|---|

| I/O cables | Standard I/O cable set | Consisting of 8-m I/O cables for "Mini I/O" and "HAND I/O." |

|

|

Consisting of 15-m I/O cables for

"Mini I/O" and "HAND I/O."

|

|||

| I/O cable for "Mini I/O" (68 pins) | 8 m | ||

| 15 m | |||

| I/O cable for "HAND I/O" (20 pins) | 8 m | ||

| 15 m | |||

| I/O cable for "Parallel I/O board" (96 pins) | 8 m | ||

| 15m | |||

| Operation devices | Teaching pendant | With 4 m cable | |

| With 8 m cable | |||

| With 12 m cable | |||

| Mini-pendant kit (Incl. WINCAPS III Light version) |

With 4 m cable | Japanese language version | |

| English language version | |||

| With 8 m cable | Japanese language version | ||

| English language version | |||

| With 12 m cable | Japanese language version | ||

| English language version | |||

| Pendant extension cable | 4 m | For TP / MP | |

| 8 m | For TP / MP | ||

| For VS | External battery unit | With 4 m cable | |

| With 8 m cable | |||

| With 12 m cable | |||

| Brake release unit | With 4 m cable | ||

| With 8 m cable | |||

| With 12 m cable | |||

| Air purge unit | Only for protected type robots | ||

| Second arm cover R (with tapped holes) for VS-050 / 060 |

Only for standard type robots(IP40) | ||

| Second arm cover R (with tapped holes) for VS-068 / 087 |

Only for standard type robots(IP40) | ||

| Stopper bolt M8 for J2 mechanical ends for VS-050 / 060 |

For the 2nd axis | ||

| Stopper bolt M5 for J3 mechanical ends for VS-050 / 060 |

For the 3rd axis | ||

| Stopper bolt M10 for J2 / J3 mechanical ends for VS-068 / 087 |

For the 2nd and 3rd axes | ||

| For HM | Flange kit | For 20 kg payload | |

| For 10 kg payload | |||

| For HS | Flange kit | For 5 kg payload | |

| For XR | Valve assembly 4-station manifold valve |

Single shipment (supply part) | |

| Robot mounting shipping | |||

| Hand control cabling kit | - | ||

| Hand control cable | 2m | ||

| Item / Specifications | ||

|---|---|---|

| VM/VP/HM/HS/XR Series Standard cable (for standard type) |

Straight | 2 m |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| Angle | 2 m | |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| VM/VP/HM/HS/XR Series Splash-proof cable (for dust- & splash-proof type and cleanroom type) |

Straight | 2 m |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| Angle | 2 m | |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| For VS-050/VS-060/ VS-068/VS-087 |

Straight | 2 m |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| Angle | 2 m | |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| Type | Item | ||

|---|---|---|---|

| Optional boards for the robot controller RC8 series |

Parallel I/O board (PCI board) |

NPN type I/O | Shipped after mounted on the controller (With license) |

| Shipped separately as a spare part (With license) |

|||

| Shipped separately as a spare part (Without license) |

|||

| License certificate only | |||

| PNP type I/O | Shipped after mounted on the controller (With license) |

||

| Shipped separately as a spare part (With license) |

|||

| Shipped separately as a spare part (Without license) |

|||

| License certificate only | |||

| DeviceNet slave board (PCI Express board) |

Mobile unit | Shipped after mounted on the controller (With license) |

|

| Shipped separately as a spare part (With license) |

|||

| Shipped separately as a spare part (Without license) |

|||

| License certificate only | |||

| CC-Link remote device board (PCI Express board) |

Shipped after mounted on the controller(With license) | ||

| Shipped separately as a spare part(With license) | |||

| Shipped separately as a spare part(Without license) | |||

| License certificate only | |||

| PROFIBUS slave board (PCI Express board) |

Shipped after mounted on the controller(With license) | ||

| Shipped separately as a spare part(With license) | |||

| Shipped separately as a spare part(Without license) | |||

| License certificate only | |||

| EtherNet/IP Adapter board (PCI Express board) |

Shipped after mounted on the controller(With license) | ||

| Shipped separately as a spare part(With license) | |||

| Shipped separately as a spare part(Without license) | |||

| License certificate only | |||

| Electric Gripper Control board (PCI board) |

Shipped after mounted on the controller(With license) | ||

| Shipped separately as a spare part(With license) | |||

| Shipped separately as a spare part(Without license) | |||

| License certificate only | |||

| VGA option for RC 8 | VGA junction cable set*1 | VGA junction cable VGA connector is mounted on the controller before shipping. |

|

| Options for Installation | Stay set for wall-mount | Wall-mount / Floor-mount | |

| Item / Specifications | ||

|---|---|---|

| For HS·HM·VM·VP·XR Series VS-6556·VS-6577 Standard cable (for standard type) |

Straight | 2 m |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| Angle | 2 m | |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| For HS·HM·VM·VP·XR Series VS-6556·VS-6577 Splash-proof cable (for dust- & splash-proof type and cleanroom type) |

Straight | 2 m |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| Angle | 2 m | |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| XYC Series Standard cable |

Straight | 4 m |

| 6 m | ||

| For VS-050/VS-060/ VS-068/VS-087 |

Straight | 2 m |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

| Angle | 2 m | |

| 4 m | ||

| 6 m | ||

| 12 m | ||

| 20 m | ||

If you have not registered

The services on this member site are available only for registered customers.