They are suitable for transportation, palletising and depalletizing operations which makes workers free from hard labor.

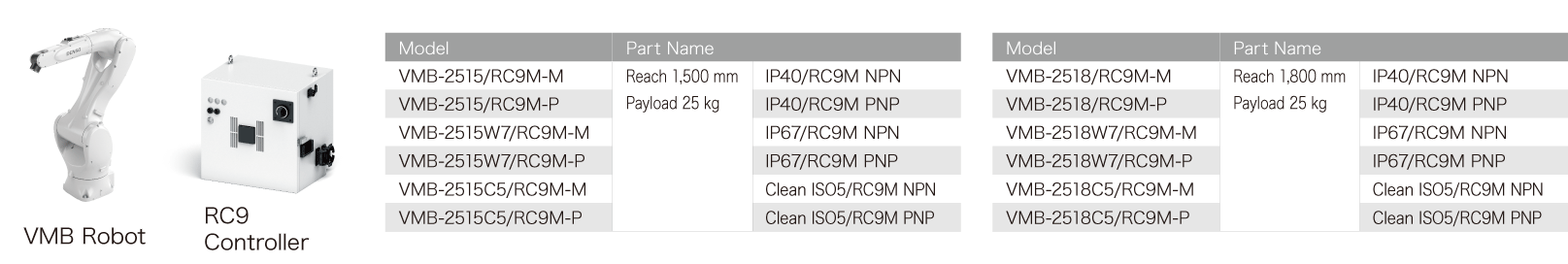

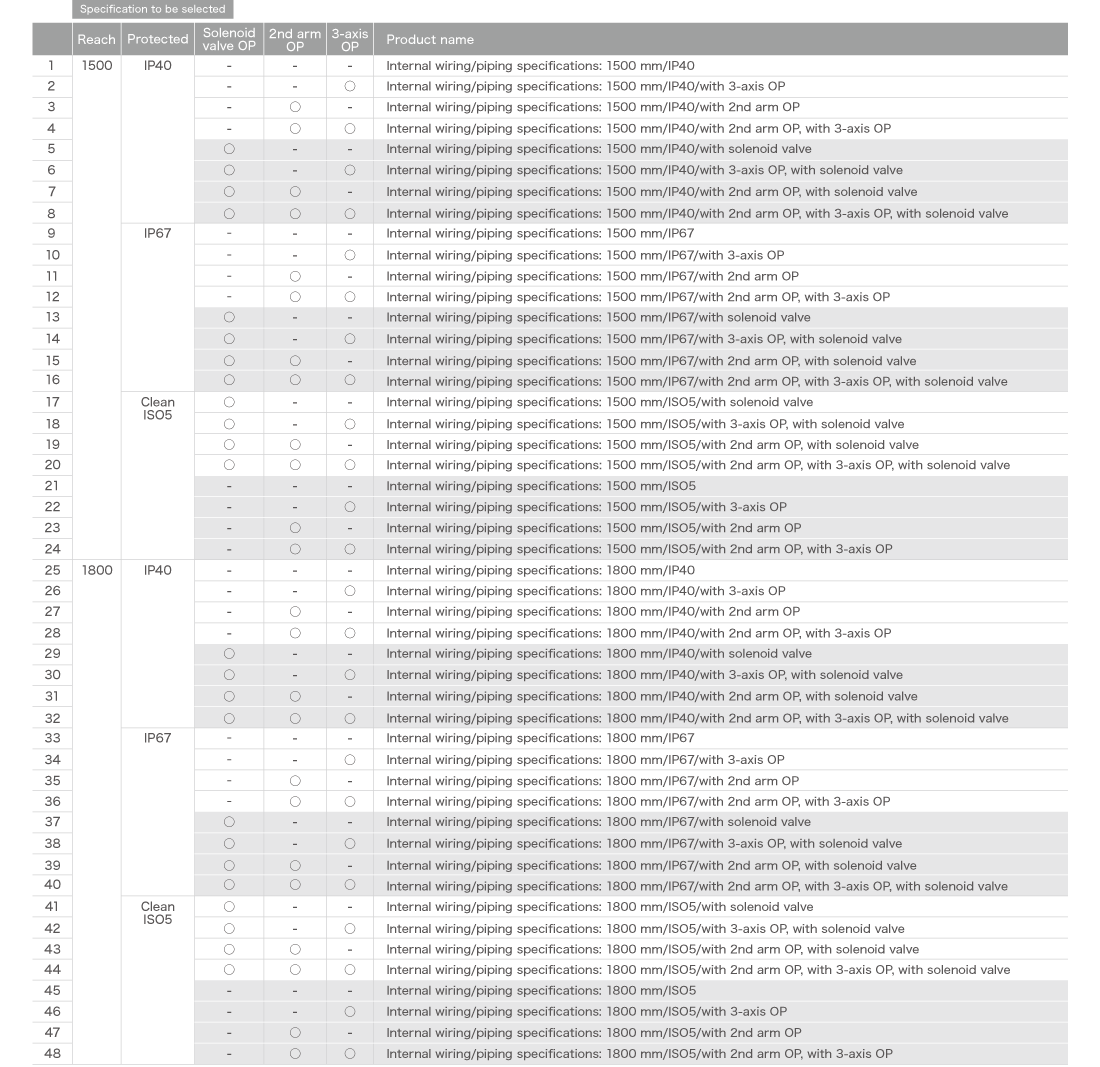

Maximum arm reach|1506・1804mm

Maximum payload|25kg

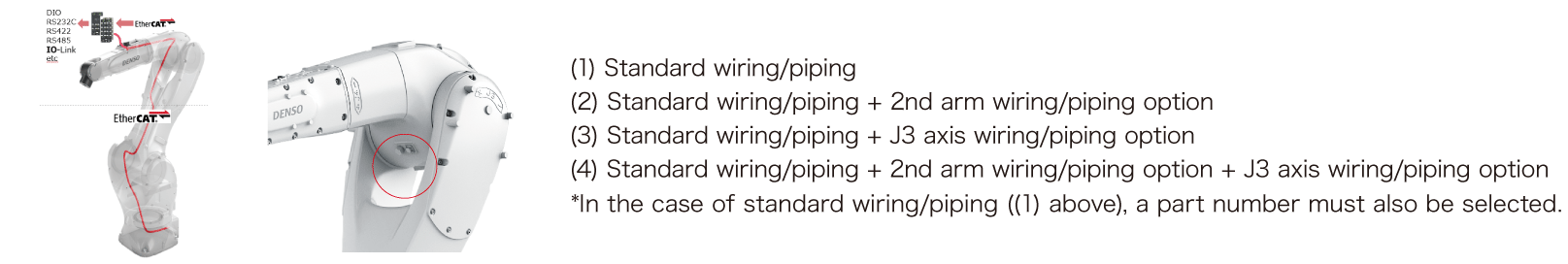

Enable to attach various sensors and other devices on the robot arm with enhanced user wiring, piping, valves, and newly added internal wiring EtherCAT.

Reduced the hassle of wirings and pipings around the robot arm.

In addition to the standard type, having the robot line-up which is complied with the dust- and splash-proof (protection grade IP67) and Cleanliness (ISO class 5), which applies to electrical and electric parts, food manufacturing processes and pharmaceutical and medical devices, etc. that are required strict conditions for sanitation and cleanliness.

A backup battery for the encoder can be installed externally to the robot.

This allows easier battery replacement and improved maintenance.

A switch that allows you to release the brake of each axis (the wiring of this switch is directly connected to the brake release signal of each axis).

| Item | Unit | Specifications | ||||

|---|---|---|---|---|---|---|

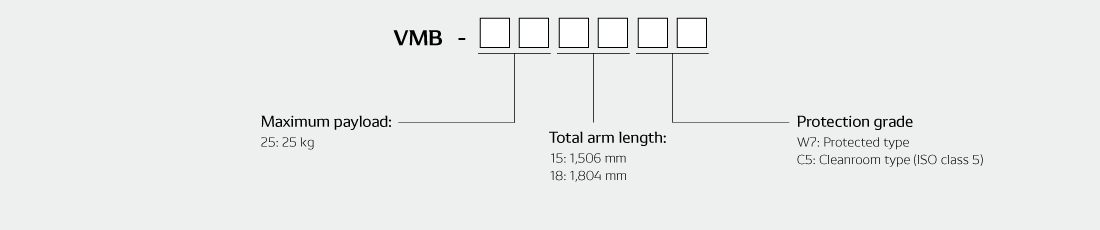

| Robot Model | - | VMB-2515 | VMB-2518 | |||

| Axes | - | 6 | ||||

| Drive motor / brake | - | All-axis AC servo motor / all-axis with brakes | ||||

| Total arm length (Arm 1 + Arm 2) | mm | 1395 (710+685) | 1695 (860+835) | |||

| Maximum operating area | mm | 1506 (Point P: J4, 5, 6 Axis center) | 1804 (Point P: J4, 5, 6 Axis center) | |||

| Operating range | J1Axis | ° | -170 ~ 170*¹ | |||

| J2Axis | ° | -100 ~ 140 | ||||

| J3Axis | ° | -130 ~ 170 | ||||

| J4Axis | ° | -200 ~ 200 | ||||

| J5Axis | ° | -145 ~ 145 | ||||

| J6Axis | ° | -360 ~ 360 | ||||

| Maximum payload | kg | 25 | ||||

| Maximum speed | J1Axis | deg/s | 240 | 212 | ||

| J2Axis | deg/s | 240 | 212 | |||

| J3Axis | deg/s | 300 | 270 | |||

| J4Axis | deg/s | 425 | ||||

| J5Axis | deg/s | 425 | ||||

| J6Axis | deg/s | 887 | ||||

| Position repeatability (at the center of a tool mounting face)*2 | mm | In each of X, Y and Z directions: ±0.05 | ||||

| Maximum allowable moment | Around J4Axis | N・m | 52 | |||

| Around J5Axis | N・m | 52 | ||||

| Around J6Axis | N・m | 32 | ||||

| Air piping | 2nd arm unit | Without option | - | 2 systems (φ8 × 2) | ||

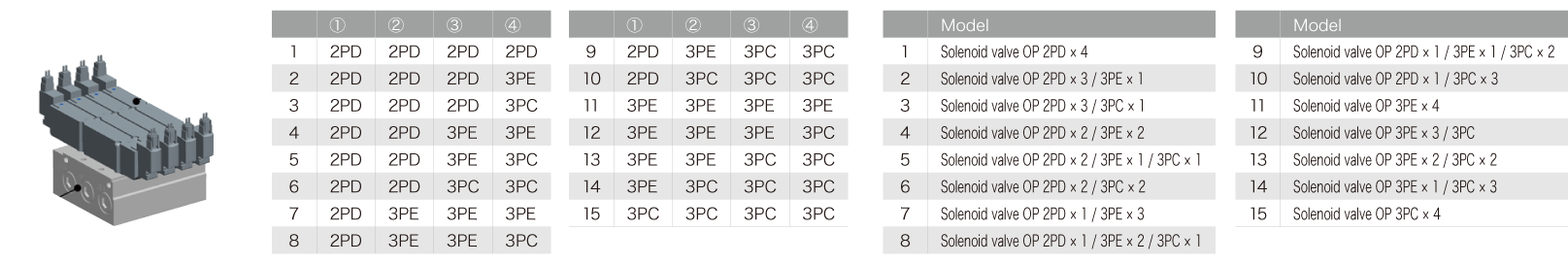

| With option | - | 1 system (φ8 × 1) Solenoid valves dedicated 8 systems(φ6 × 8) - Select a combination of solenoid valves from a, b and c. a. 2-position, Double Solenoids b. 3-position, Exhaust Center Solenoids c. 3-position, Closed Center Solenoids |

||||

| 3-axis unit | Without option | - | 0 | |||

| With option | - | 1 system (φ8 × 1) | ||||

| Signal line, Ethernet | 2nd arm unit | Without option | - | Signal line : 15 Ethernet cable : 1 |

||

| With option | - | Signal line : 15 + 10*³ >Ethernet cable : 1 + 1 |

||||

| 3-axis unit | Without option | - | Signal line : 0 | |||

| With option | - | Signal line : 10 | ||||

| Air source | Operating pressure | MPa | 0.20 to 0.39 | |||

| Allowable maximum pressure | MPa | 0.49 | ||||

| Noise (Equivalent continuous A-weighted sound pressure level) | dB | 75 | ||||

| Protection class | - | Standard type : IP40 Severe environment type : IP67 |

||||

| Clean level (ISO 14644-1) | - | Class 5 (Cleanroom type) | ||||

| Pollution degree*⁴ | - | Standard type : 2*⁵ Protected Type : 3 Cleanroom Type : 2 |

||||

| Weight | kg | Approx. 230 | Approx. 250 | |||

If you have not registered

The services on this member site are available only for registered customers.