They are suitable for transportation, palletising and depalletizing operations which makes workers free from hard labor.

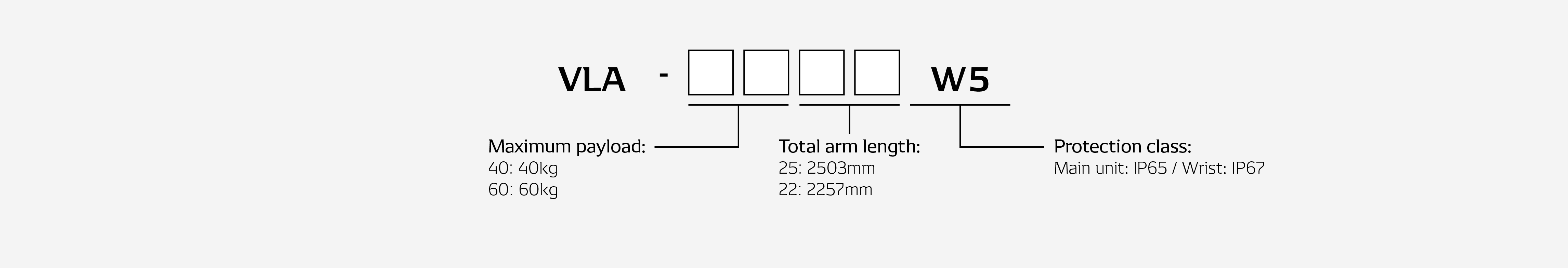

Maximum arm reach|2503 / 2257 mm

Maximum payload|40 / 60 kg

The VLA series boasts high payload capability and long arm reach. A new member to the series, the VLA-6022 offers the highest payload of 60 kg (132lb) among DENSO robotics. The VLA-6022 is suitable not only for automation of transportation and inspection but also for palletizing, depalletizing and packaging processes.

Complied with the protection grade IP67(*) and contribute to automate under severe environments that an oil or water mist scatters.

*Complied with IP67 for wrist, IP65 for unit.

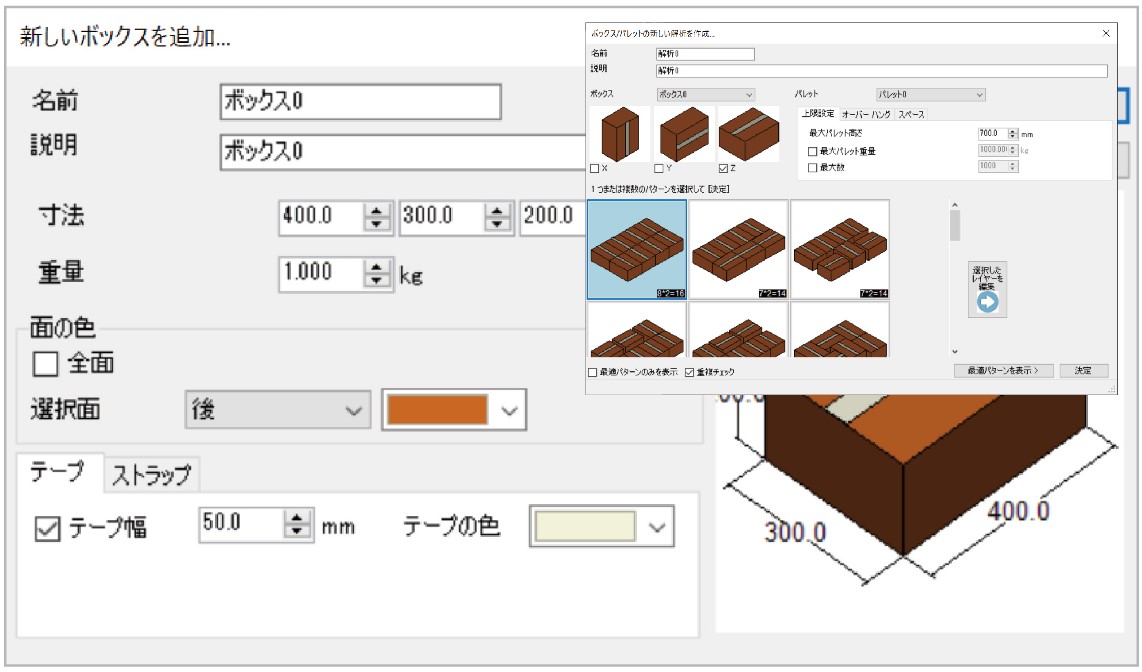

When combined with "Palletizing Builder," which is an option with WINCAPS Plus Offline Programming software suite, the palletizing process can be automated.

The field network is wired inside the robot, reducing the complexity of the external wiring.

Compatible communication standards : PROFINET, PROFIBUS, DeviceNet

Field networks such as DeviceNet are wired inside the robot, reducing the complexity of external wiring.

Not adjustable horizontally

Not adjustable horizontally

| Item | Unit | Specifications | ||||

|---|---|---|---|---|---|---|

| Robot Model | - | VLA-4025 | VLA-6022 | |||

| Axes | - | 6 | ||||

| Position detection system | - | Absolute Encoder | ||||

| Drive motor / brake | - | All-axis AC servo motor / all-axis with brakes | ||||

| Overall arm length(first arm + second arm) | mm | 2085.5 (860+1,225.5) | 1835.5 (860+975.5) | |||

| Maximum operating area | mm | 2503 (Point P: 4th, 5th, 6th axis center) | 2257 (Point P: 4th, 5th, 6th axis center) | |||

| Motion range | 1st axis | ° | -180 ~ 180*¹ | |||

| 2nd axis | ° | -60 ~ 125 | ||||

| 3rd axis | ° | -160 ~ 0 | ||||

| 4th axis | ° | -2700 ~ 2700*⁴ | ||||

| 5th axis | ° | -123 ~ 123 | ||||

| 6th axis | ° | -2700 ~ 2700*⁴ | ||||

| Maximum payload | kg | 40 | 60 | |||

| Position repeatability (at the center of a tool mounting face) *² | - | In each of X, Y and Z directions: ±0.06 | ||||

| Maximum allowable moment | Around 4th | N・m | 167 | 221 | ||

| Around 5th | N・m | 167 | 221 | |||

| Around 6th | N・m | 98 | 118 | |||

| Air piping | - | 1 system (inner diameter: φ12.5) | ||||

| Signal line | - | 14-core (19-core connector) | ||||

| - | 15-core (17-core connector)*³ | |||||

| Air source | Allowable maximum pressure | MPa | 2.0 | |||

| Noise (Equivalent continuous A-weighted sound pressure level) | dB | 75 | ||||

| Protection class | - | Main unit: IP65 / Wrist: IP67 | ||||

| Weight | kg | Approx. 655 | Approx. 645 | |||

If you have not registered

The services on this member site are available only for registered customers.