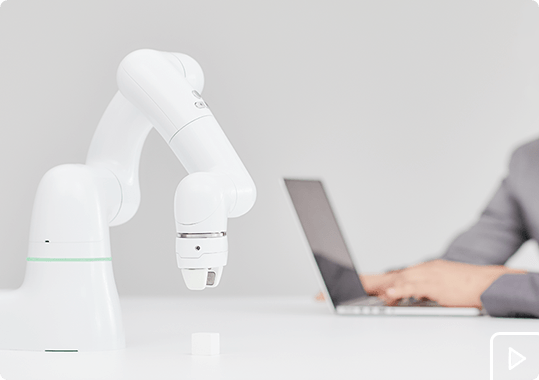

Anywhere, anytime, hassle-free. A robot that collaborates with everyone.

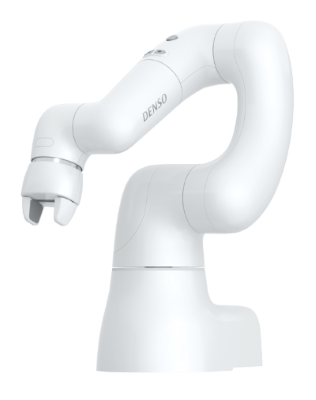

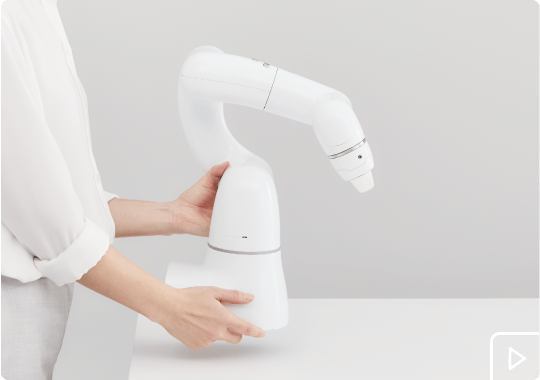

With the initial purpose of increasing the productivity of our own automobile component manufacturing facilities, we have been developing DENSO robots for 50 years. Today, we introduce the new collaborative robot “COBOTTA" The human-friendly, compact, and portable design allows you to take COBOTTA anywhere, and automate tasks right away. No expert knowledge is required, making operation amazingly easy. Do you need that extra hand? Do you want to leave simple tasks to robots, and make more time for creative work? COBOTTA will open infinite possibilities to address your needs, and realize creative, new ideas.

Collaborative robots do not require safety fences. The unique outer contour has no sharp edges, and consists of curves that prevent hands from getting caught. Sensors are built into the six moving parts for constant monitoring of speed and torque, to guar-antee safety from a function-al aspect (planning to obtain certification from a third-par-ty certification authority).

The main unit weighs approximately 4 kg providing easy portability, and offers a load capacity of 500 g. The integrated controller not only reduces wiring, but also allows consolidated control with other devices. ORiN is supported as standard.

Equipped with a direct teaching function and an intuitive GUI for easy programming. An optional camera can be mounted to enable teaching using the camera.

The integrated controller is open, and COBOTTA's control API is made public, allowing creators to develop their own applications in the environment they choose (OSS version).

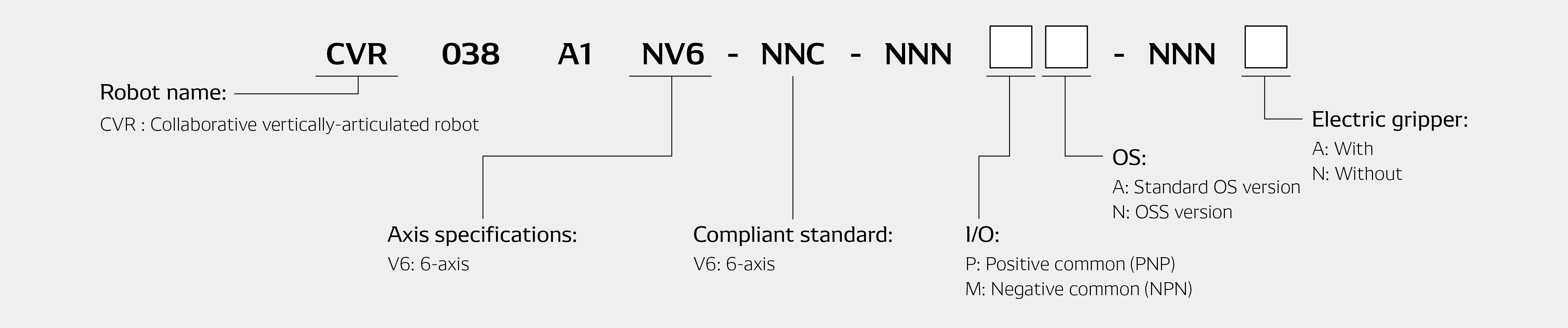

| Axes | J6Axis (arm unit)+ J1Axis (electric gripper unit)*¹ |

|---|---|

| Drive motor / brake | All axes AC servo motor/1, 2, 3, 4 and 5 Axis with brake |

| Total arm length (1st arm+ 2nd arm) | 342.5 ( 165+ 177.5) mm |

| Rated load capacity (Maximum payload) | 0.5 kg (0.7 kg within土10 degrees with the wrist angled downward)*² |

| Maximum speed | J1Axis:23.1 deg/s J2Axis:22.47 deg/s J3Axis:41.58 deg/s J4Axis:42.35 deg/s J5Axis:42.35 deg/s J6Axis:63.56 deg/s |

| Position repeatability | ±0.05mm*³ |

| Maximum composite speed (center of tool mounting face) |

4.32 sec in the factory configuration, 1.6 sec when set to maximum speed (Reciprocating movement time for 200 mm in the horizontal direction and 25 mm in the vertical direction) |

| Degree of protection | COBOTTA unit : IP30 AC adapter and AC cable : IP20 |

| Software | Standard version: COBOTTA-dedicated software OSS version: None (*Linux, etc. may be installed by the customer) |

| Power supply specifications (AC adaptor) | Input : Single-phase AC100 - 240 V土10%/47 - 63 Hz |

| External signal | Dedicated input : 12 points / Dedicated output: 71 points General-purpose input: 8 points / General-purpose output: 9 points External emergency stop connection x 1 ch |

| External communication | Ethernet x 1 line, USB x 2 lines, VGA output x 1 ch |

| Weight | Approx. 4 kg |

| Safety specifications | Standard Version : ISO 10218-1:2011, ISO/TS 15066:2016, ISO 13849-1:2023 PL d, Cat. 3 OSS version : ISO 13849-1:2023 PL d, Cat. 3 |

| Noise (Equivalent continuous A-weighted sound pressure level) | 55 dB or less (Measured with the rated payload and the maximum speed of the factory default setting) |

| Pollution degree*⁴ | 2 |

| Overvoltage category | Ⅱ*⁵ |

| standard | |

|---|---|

| COBOTTA | Download |

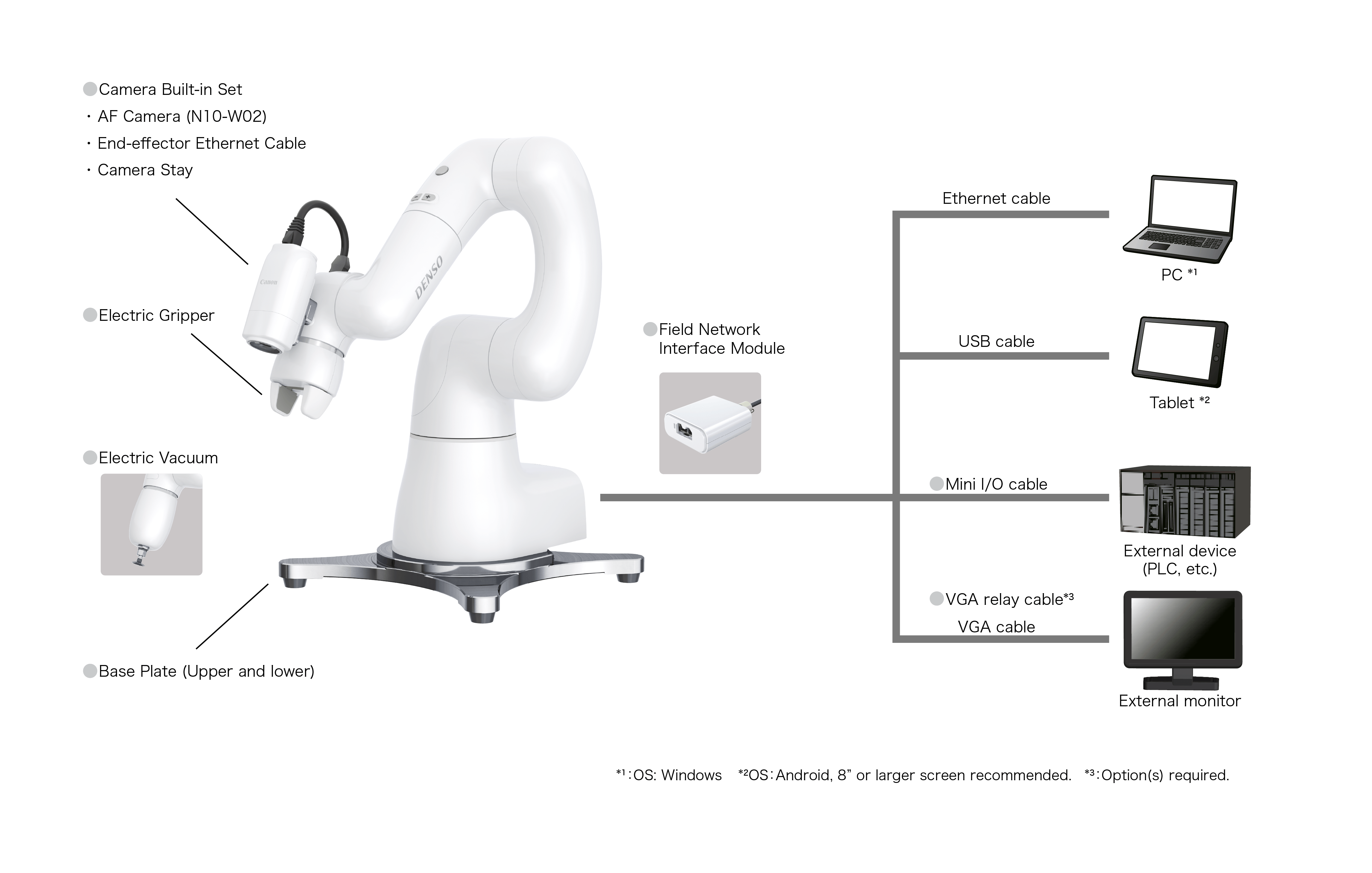

■Electric gripper*¹

This hand-mounted tool is suitable for basic operations such as "grip" and "release."

■Electric vacuum generator*¹

This tool achieves adsorption easily without any external compressor.

■Camera built-in set*¹*²

This enables the worker to perform work while visually confirming the workpiece position. Since the product is calibrated at the factory before shipping, the product can be used immediately without initial setting.

■Base plate (Upper and lower)

The base plate is used to set up and operate a COBOTTA robot without securing it in place. This 2-part base plate consists of upper and lower sections.

■Field network interface module

The interface module supports EtherCAT, EtherNet/IP and PROFINET.

■VGA relay cable*³

This cable connects to a commercially available VGA cable for connection to an external monitor.

■Mini I/O cable

Communication cable to connect COBOTTA to external devices.

If you have not registered

The services on this member site are available only for registered customers.