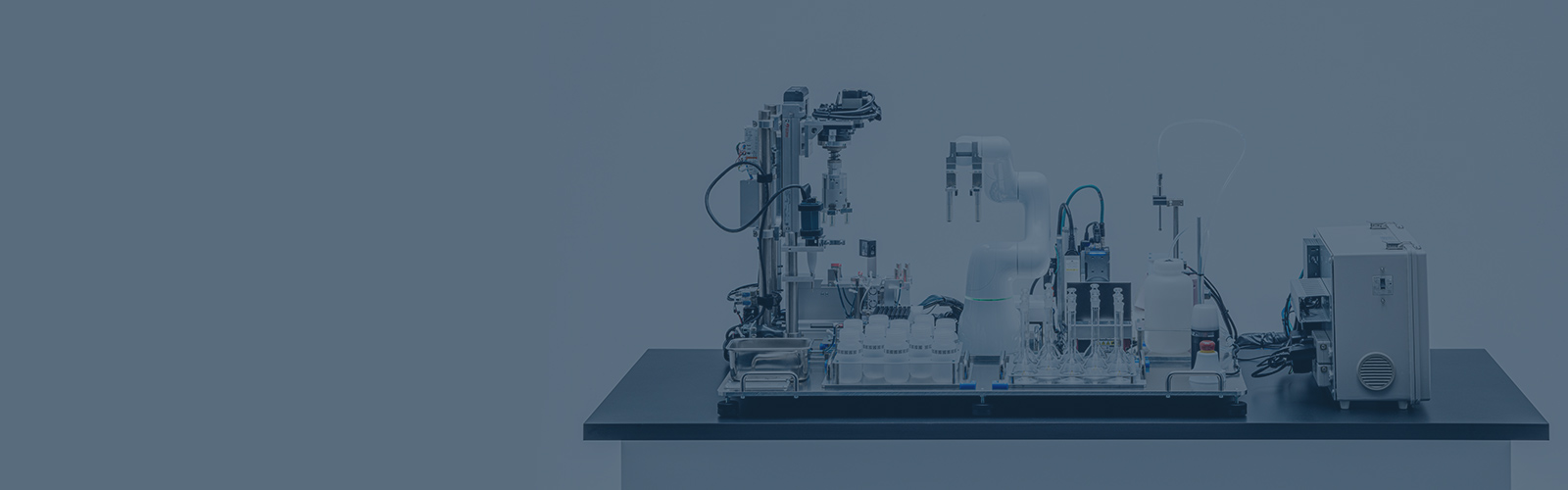

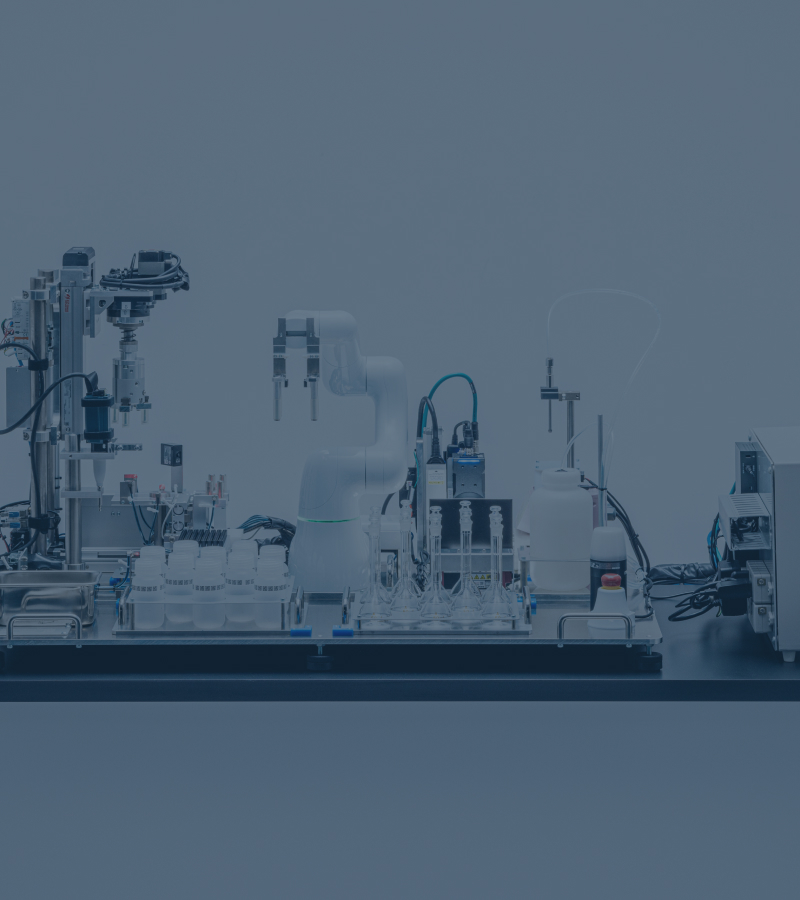

Fixed capacity system

Accurately reproduces complicated movements for fixed capacity control

This system automates a series of tasks related to fixed capacity control for liquids, such as dispensing multiple types of liquids, performing precise fixed capacity control through image recognition, and mixing liquids. It automates tasks that are prone to variability, allowing consistent experiment data to be collected.

Operation overview

System specifications

| Dispensing volume | 5 to 200 μl, 40 to 1,000 μl, 100 to 5,000 μl |

| Dispensing precision | 200 μl ±1%, 1,000 μl ±0.45%, 5,000 μl ±0.5% |

| Accuracy | 200 μl ±0.3 %, 1,000 μl ±0.15 %, 5,000 μl ±0.15 % |

| System dimensions | Approx. 1,000 mm (W) × 650 mm (D) × 550 mm (H) |

| Weight | Approx. 50 kg |

| Power supply | Single-phase 100 VAC 15 A |

Available containers

-

PP bottles

50 ml, 100 ml

-

Measurement flasks

25 ml, 50 ml, 100 ml

-

Screw-top bottles

50 ml, 100 ml

-

Beakers

50 ml, 100 ml

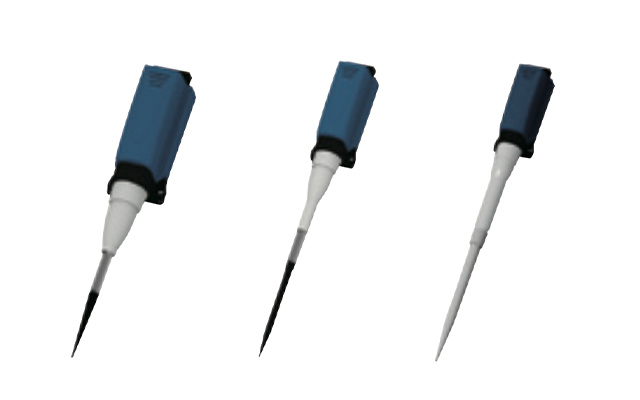

System usage parts

-

Electric pipettes

Sartorius

rLine embedded pipette

| Specifications | |

|---|---|

| Volume variations |

5 to 200 μl, 40 to 1,000 μl, 100 to 5,000 μl |

-

Liquid pump

TACMINA Q Series

| Specifications | |

|---|---|

| Dispensing amount | 0.1 to 100 ml/min |

| Reproducibility | ±1 % |

| Transfer fluid viscosity | 200 mPa/s or less |

| Protection grade | IP65 |

*Specifications may be changed