Yosuke Sawada

General Manager

Product Planning Department, Engineering Planning Division, Control System Business Group

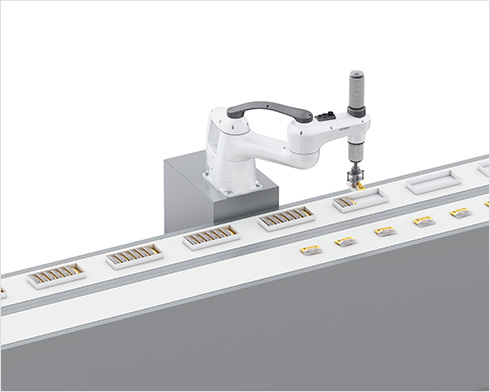

The HSR Series robots are new high-speed selective compliance assembly robot arm (SCARA) robots that have unprecedented high-speed performance and improved lightweight and stiffness properties. Yosuke Sawada, the General Manger of the Product Planning Department, has led the planning team of this series. He says, “The performance of a robot often cannot be measured by the numerical values shown in the catalogue.” This means that theoretical movements of the robot using the champion data that was determined by equations are different from actual movements of the robot that was introduced to the field.

Keep working at high speeds and stop instantly. Robots used in plants were required to control these movements. Sawada et al. determined to develop products focusing on cycles per minute (CPM; per-minute workload) on which the industry had ever concentrated, rather than the maximum instantaneous speed. Departure from the speed battle was a big decision. However, it was a sincere decision to respond in a serious manner to what frustrates customers after they have purchased products.

As time passes, the motors of robots that are working at high speeds generally become hot and the work accuracy become low. Sawada et al. aimed to develop robots that can keep working at high speeds even after their motors become hot. It was all about developing robots that work stably so that customers can introduce them with peace of mind. To this end, however, control design was required so that the movements of the robot arms can be controlled appropriately. Usually, robot development processes begin with machine design (determination of structures), followed by control design; however, the development team drastically changed the development processes in this project; ideal forward and backward movements of robot arms were determined through control design first. “Believing that how to move is the decisive factor for the quality of work, we advanced the development from the viewpoint of control,” says Sawada. Other members agreed to his idea and after the control design was completed, the structures of robot arms were determined so that they were best suited to the movements.

In the development processes, Sawada et al. had to overcome several barriers. The highest barrier was to achieve both lightweight and improved stiffness properties. They had to complete design that realizes elements that conflict with each other. Also, they had to take the heat dispersion characteristics of robots into account since motors become hot as robots work continuously. “To make arms lightweight, we located all motors, which have large capacity, not on the arms but on the base unit. We reviewed machine design in order to improve stiffness while keeping the robot lightweight. Furthermore, the base unit easily becomes hot due to motors working continuously at high speed. To solve this problem, we took various measures, including improving thermal conductivity and thereby enhancing heat dissipation.” Members solved these problems by simulation using PCs.

Sawada et al. successfully developed the HSR Series, whose greatest characteristic is the cycles per minute (CPM) capability. No less important is the fact that the series is the culmination of knowledge unique to DENSO WAVE. Since the company has developed robot arms and controllers on its own, the development team members have a thorough knowledge of arm characteristics (mass characteristics, inertia, etc.). For this reason, the team can pursue development under the clear vision of predicting problems that may be caused and taking preventive measures against them so that such measures lead to the improvement of productivity. For example, regarding problems caused by vibration, by creating a mechanism for restricting movements before vibration start, the robot does not start vibrating and can move on to the next move quickly, resulting in an improvement of the cycle time.

To remove frustration from customers who introduced robots, Sawada et al. started grappling with catalog values. After successfully developing the HSR Series, now they are taking on challenges in new fields. “We are aiming to not only develop robots for the automotive and electric industries, at which we have targeted, but also to develop robots that can be used for packaging processes in food, medicine and cosmetics fields. Also, we are aiming to making production lines work more smoothly by combining the HSR Series with the conveyer tracking function for products, which has been already introduced in the food, medicine and cosmetics industries (function in which a robot moves in concert with the conveyer’s movement).” They want to emphasize operability in addition to the high-speed performance. “Our teaching pendant has an interface that was carefully designed based on the cognitive engineering so that users find it easy to use it. We will continue contributing to creating an environment where users feel no strain.”