Booth

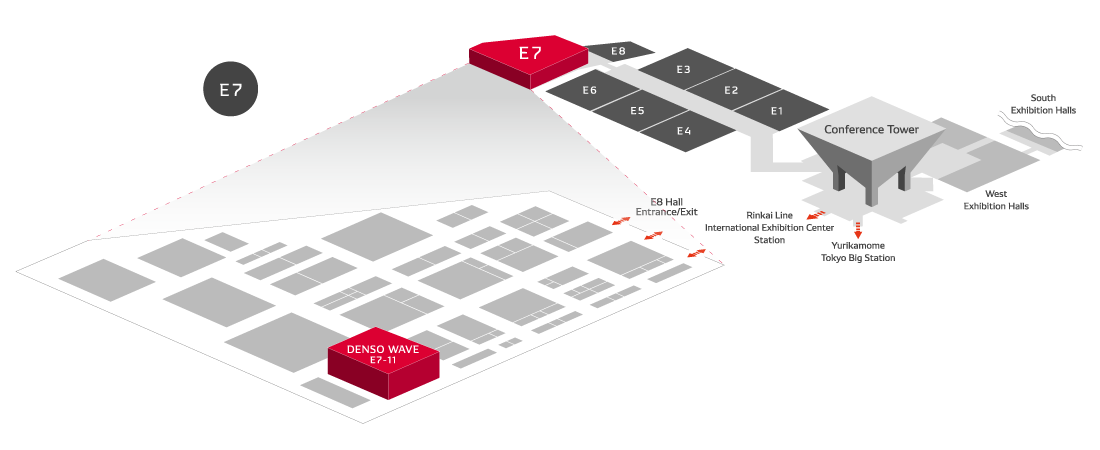

Venue Map DENSO WAVE Booth: East Exhibition Halls E7-11

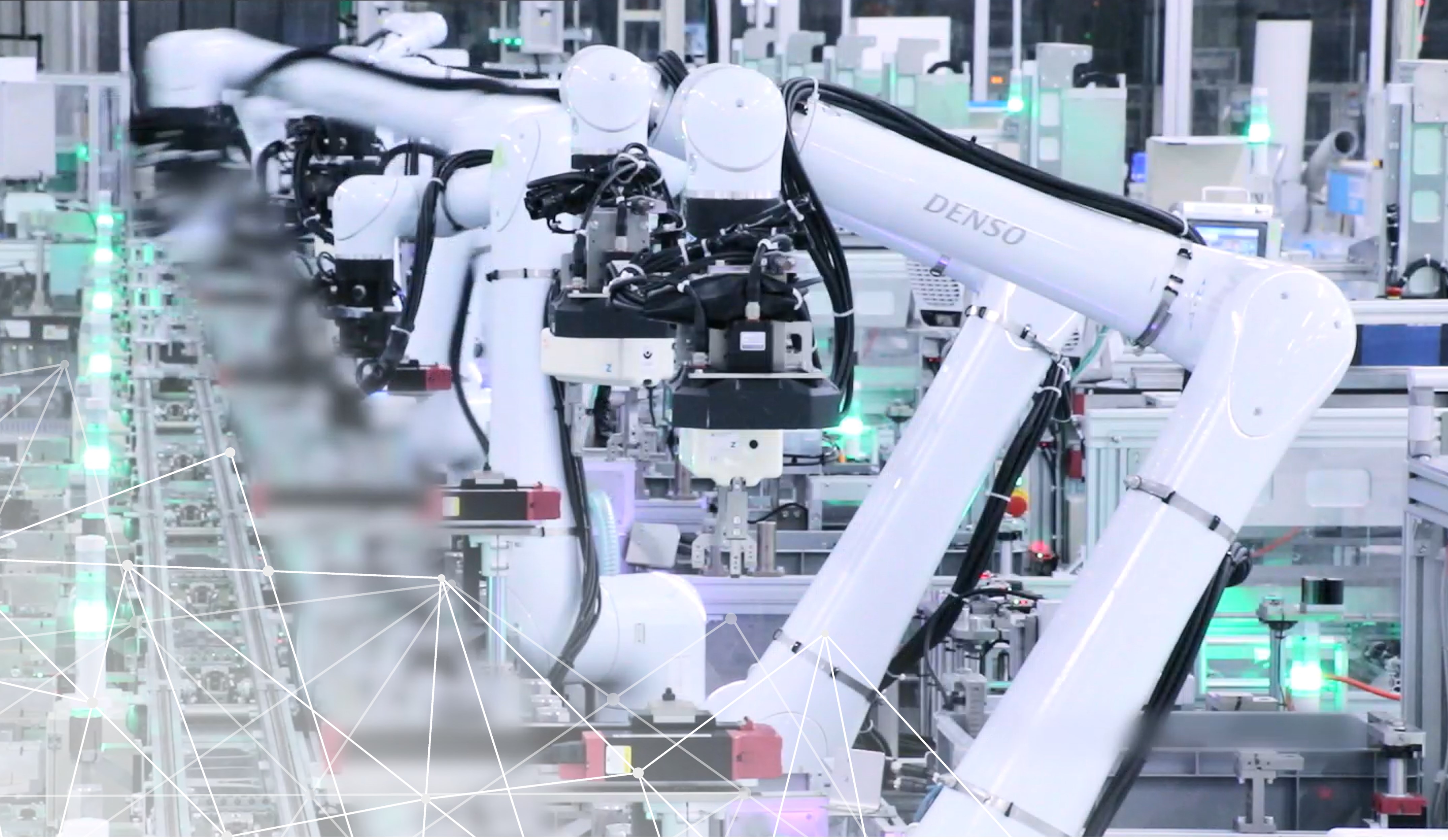

Factory

Factory Innovation

To realize the next-generation factory, we showcase automation and efficiency technologies using high-speed human-collaborative robot COBOTTA PRO, AI vision, and digital twin solutions. You can also experience a live demo of AI-powered automatic generation of optimal motion paths.

-

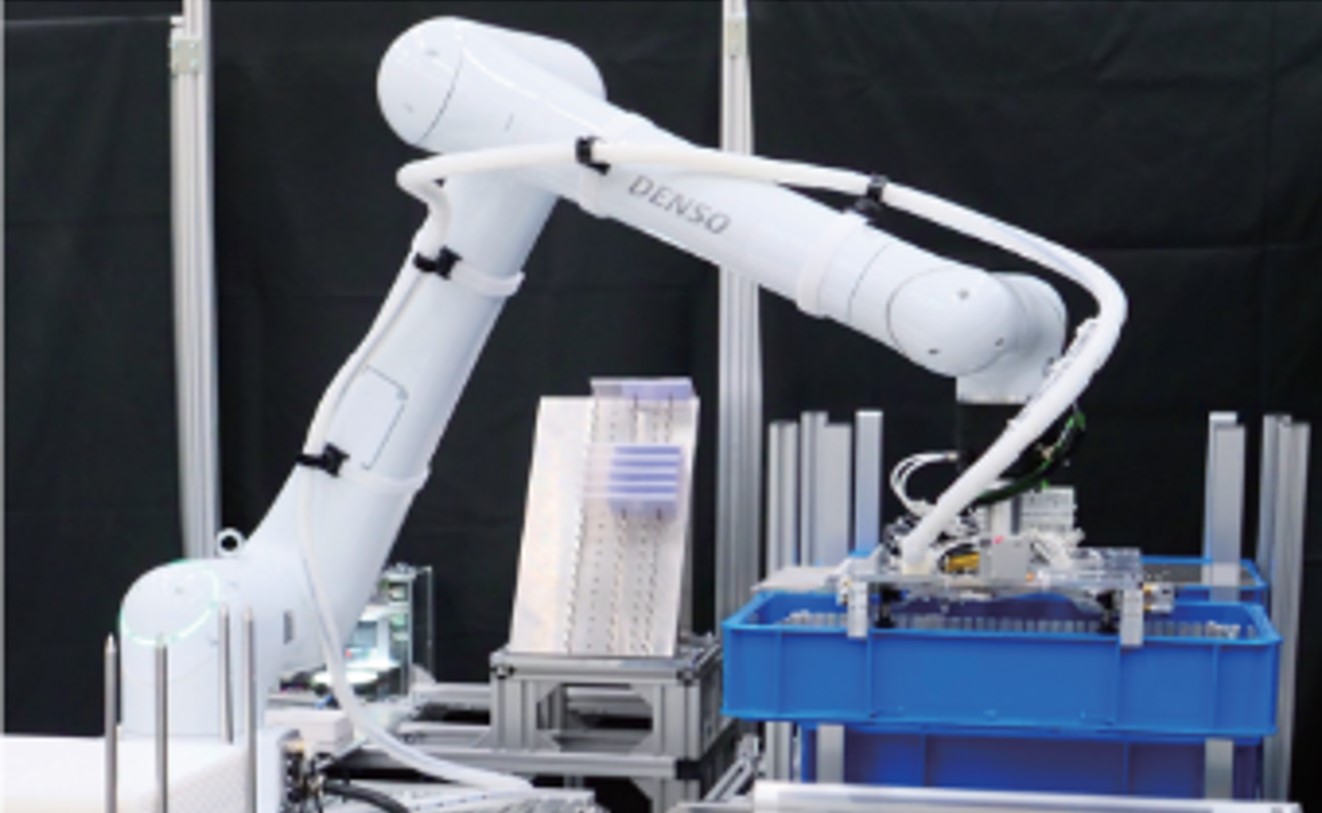

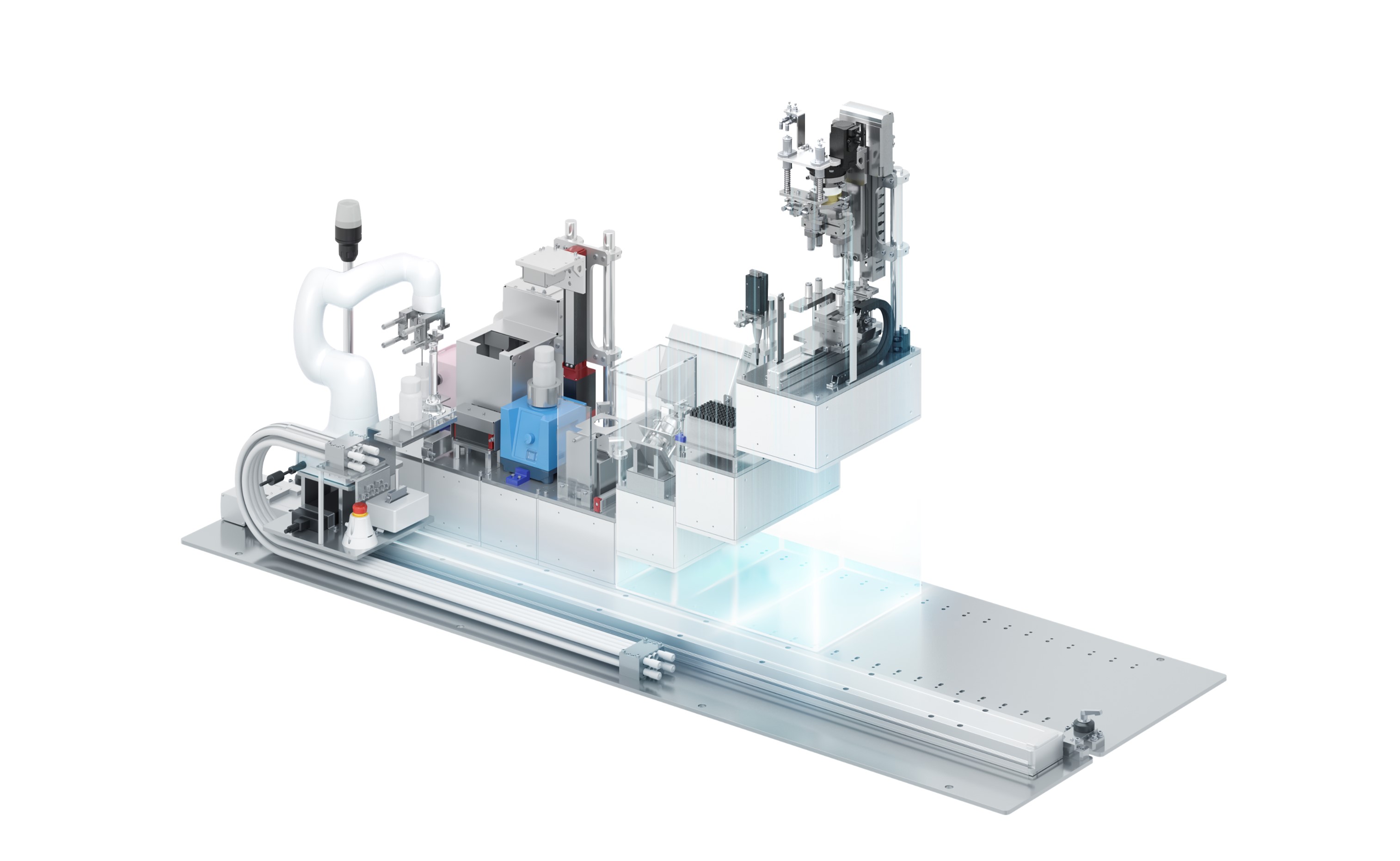

Mounting equipment reel exchange using a mobile manipulator

By combining COBOTTA PRO with an AMR, we automate reel replacement tasks on placement machines that were previously performed manually. QR code position correction and vibration damping enable coordinate correction without re-teaching and reduce cycle times.

-

Highly fast and challenging work performed by COBOTTA PRO

COBOTTA PRO features high-rigidity, high-precision torque sensors on each axis. It excels in acceleration and deceleration, enabling high-precision operations without compromising control performance. Furthermore, its touch-sensing soft cover enhances safety while increasing speed during collaborative operation, boosting productivity. Experience firsthand its top-class high-speed, high-precision motion performance among collaborative robots.

-

COBOTTA PRO: High-Difficulty Tasks Utilizing Built-in Force Sensors

The COBOTTA PRO's second arm incorporates a force sensor that detects minute changes in force in real time. This contributes to automating high-difficulty tasks such as part insertion, polishing, and inspection. At this exhibition, you can see a high-precision operation demonstration utilizing the built-in force sensor.

-

COBOTTA PRO insertion and removal of kanban cards, and transport of returnable containers.

COBOTTA PRO and our proprietary logistics gripper enable kanban insertion and removal, as well as reusable container handling, without tool changes. This achieves automated in-factory logistics and contributes to improved production efficiency.

-

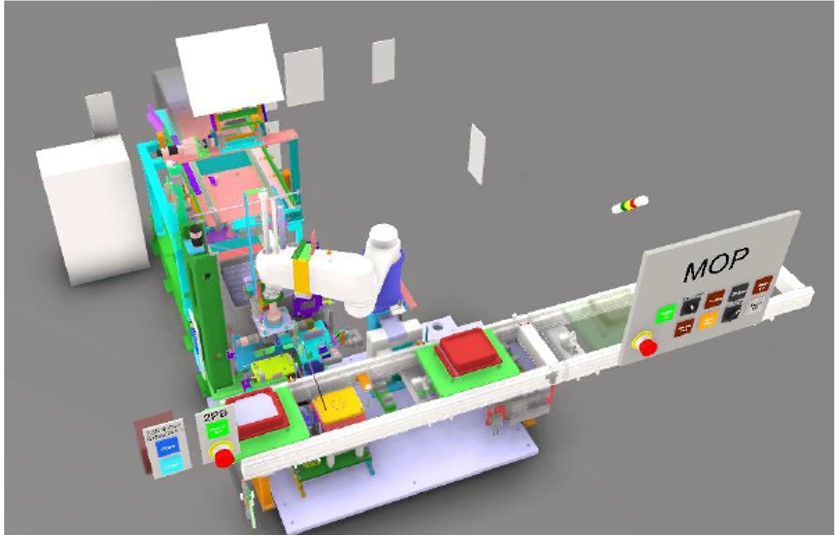

Transforming Equipment Manufacturing with Digital Twins

By syncing physical equipment with virtual spaces via digital twin technology, we visualize status and enable remote control for flexible development.This transformation introduces DENSO’s advanced production systems for next-generation factories.

-

Sealant application using real-time synchronous control

Using an EtherCAT slave-compatible RC8 controller, the robot is synchronously controlled with displacement sensors and dispensers at a 1ms cycle. This enables high-speed, high-precision sealant application while adapting to workpiece geometry and robot speed.

-

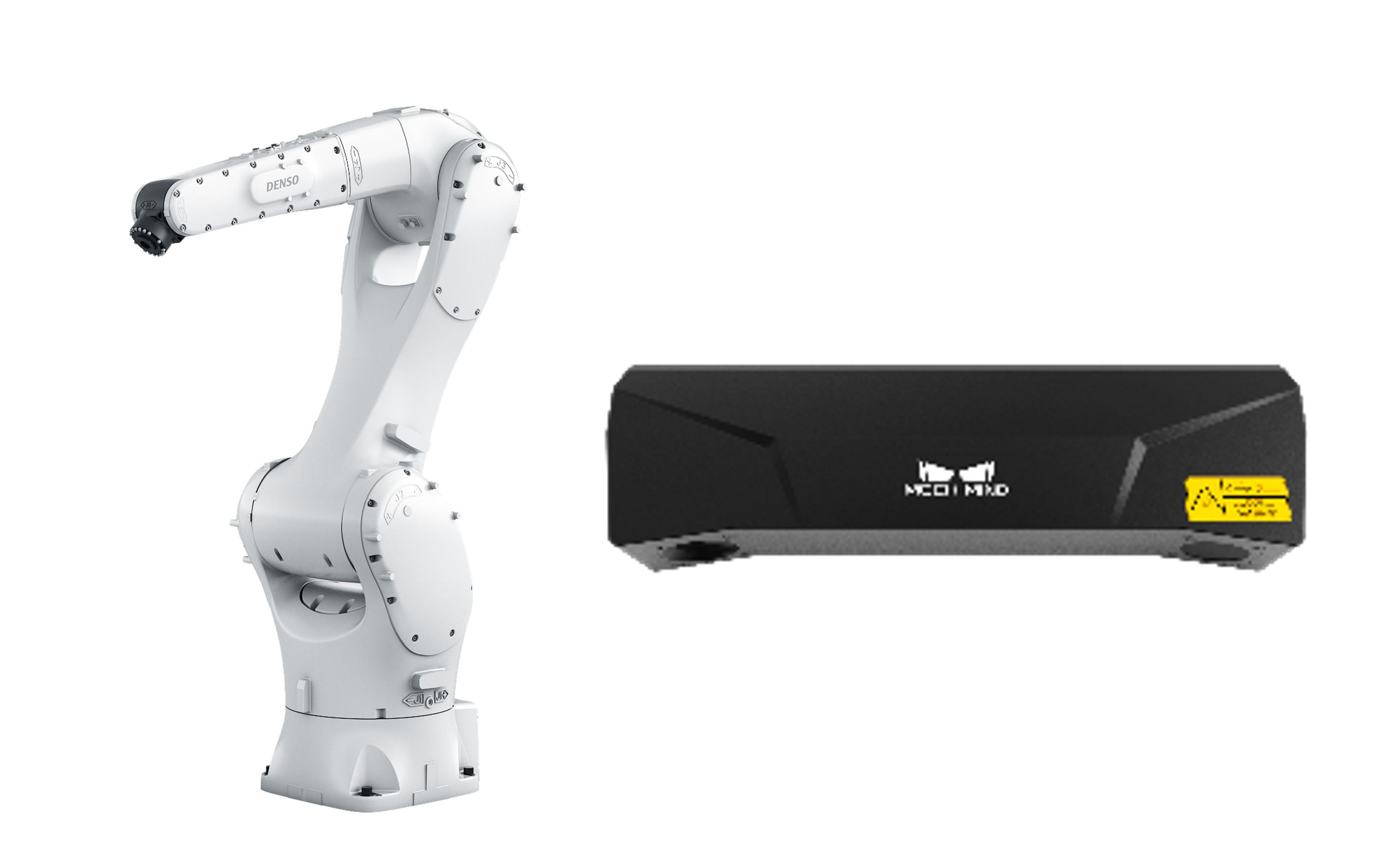

Cambrian vision system for high-speed conveyor tracking of clear workpieces

Combining the object recognition technology of the AI-equipped Cambrian Vision System with the high-speed operation of the HSR SCARA robot enables high-speed conveyor tracking of transparent workpieces.

-

Automation of Harness Assembly Using the Cambrian Vision System

The AI-equipped Cambrian vision system and the coordinated operation of two robots enable the automation of harness assembly tasks—previously difficult with conventional 3D vision systems—involving soft objects.

-

Utilizing the Latest AI Foundation Model to Control Smart Robots

One-shot learning enables intuitive teaching by allowing robots to learn actions simply by observing human demonstrations. This eliminates the need for complex programming and alignment tasks, reducing the burden of data collection and learning processes.

-

High-speed Radiator Handling with the VMB Series / Rough Placement Picking and Defect Inspection Utilizing Mech-Eye 3D Vision and AI

VMB series offers fast radiator handling with high rigidity.Its enclosed design suits harsh environments.Mech-Eye AI detects placement and inspects for foreign objects.Deep learning ensures accurate, stable recognition.

-

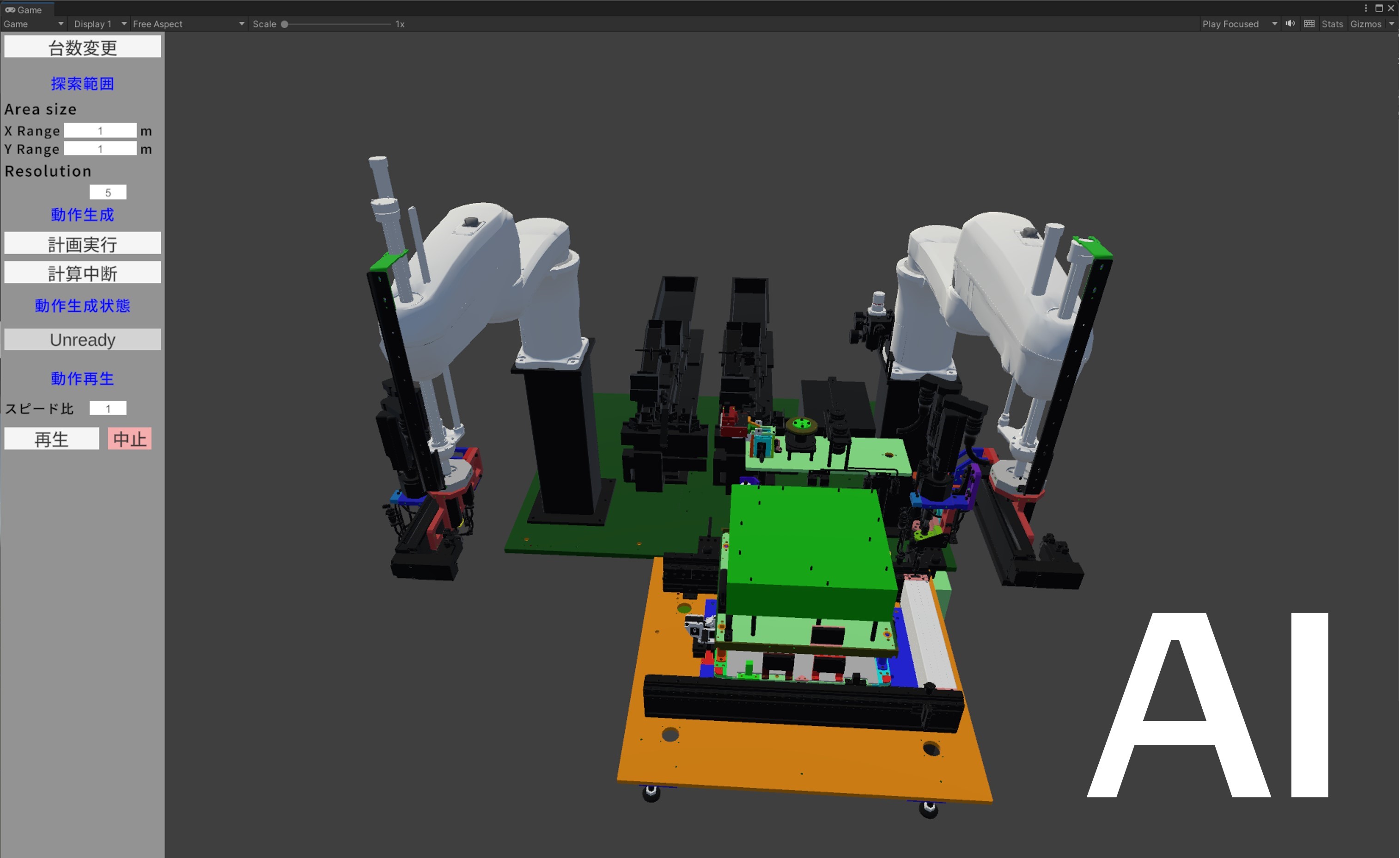

Optimal robot path/placement generated by DENSO's proprietary AI algorithm

Denso's proprietary AI algorithm automatically searches for the optimal robot placement and generates the shortest cycle time path while avoiding obstacles. This eliminates the need for trial-and-error adjustments, enabling rapid, high-productivity equipment setup.

-

Digital Twin-Based Equipment Integration Solution Utilizing the Unity Game Engine

By integrating Unity with DENSO Robotics, entire facilities are virtually replicated, enabling pre-deployment checks and faster startup.The exhibit also showcases Mech-Eye AI model generation without real footage, simplifying 3D camera setup.

-

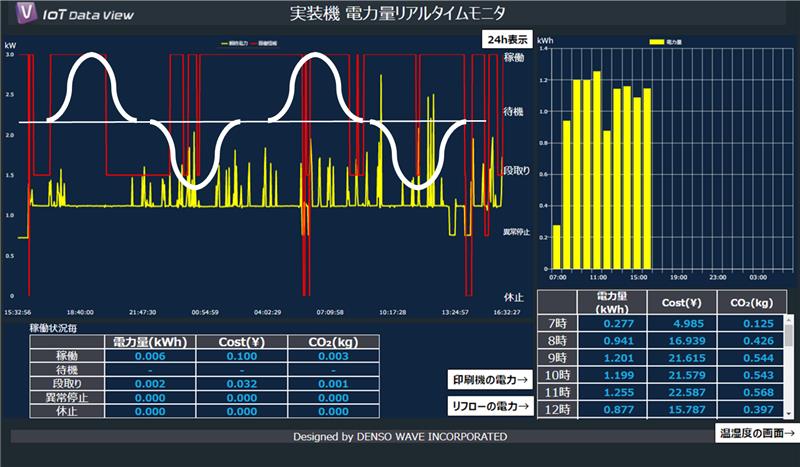

IoT Solutions for Production Equipment Energy Monitoring and Preventive Maintenance

The Production Equipment Energy KAIZEN Kit enables easy energy data collection to optimize robot operations and support energy-saving efforts.An IoT solution also visualizes robot activity, helping identify optimal maintenance timing.

Society

Robotics for Society

We present robotic solutions that leverage manufacturing expertise to address social challenges. Discover our initiatives in fields like laboratory automation and agriculture, including a tomato-harvesting robot.

-

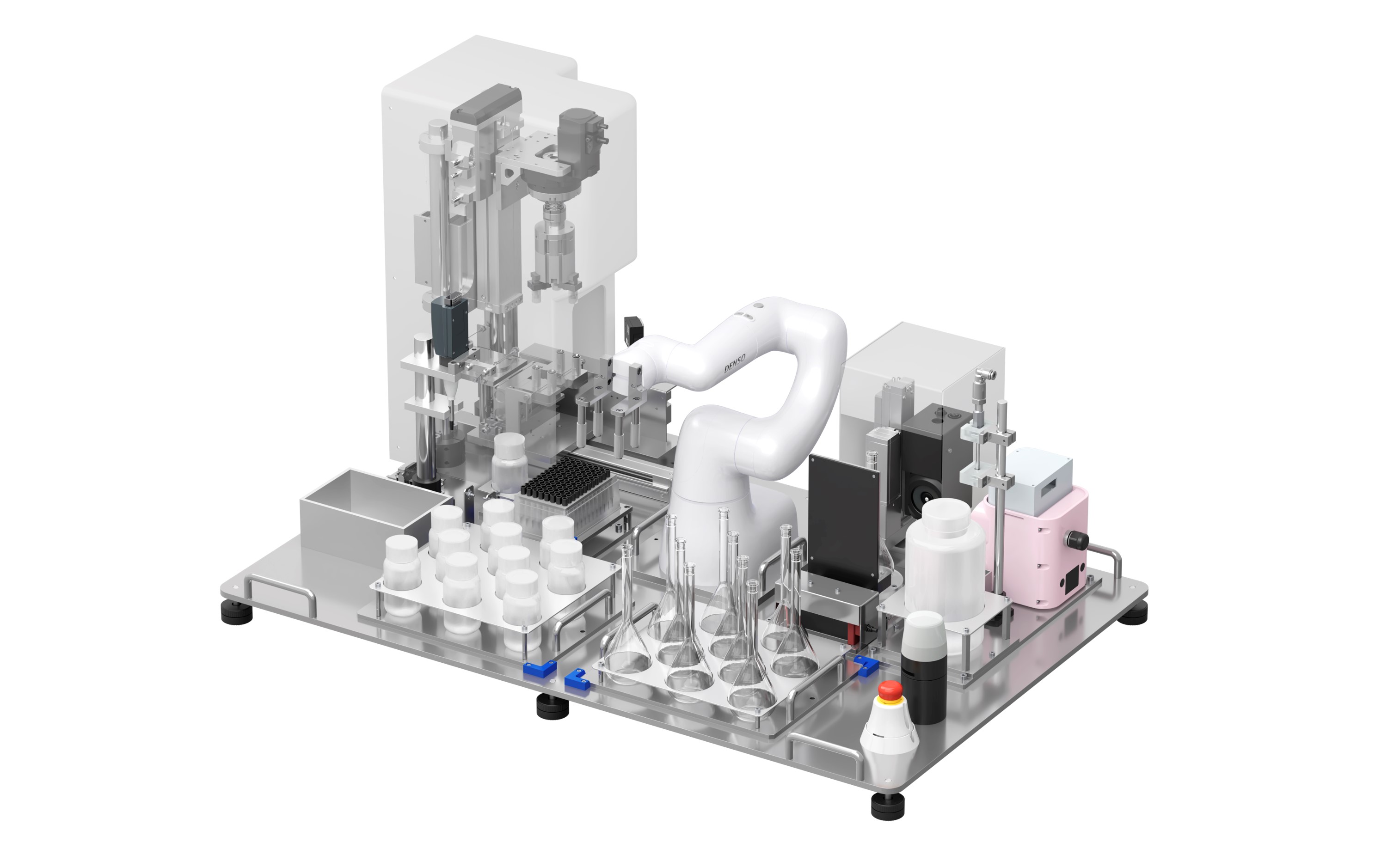

Modular Lab Automation COBOTTA LAB Modules

COBOTTA is a flexible, highly expandable system combining our proprietary standardized modules. Module combinations and layouts can be freely configured, with a sliding robot coordinating the control of multiple modules.

-

Laboratory Automation - Standard Systems -

Fixed Capasity SystemSelect the required specifications for an automation system that delivers immediate results upon implementation. It automates volumetric tasks such as dispensing multiple types of liquids, recognizing mark lines for precise measurement, and inverting and mixing liquids.

-

Aseptic Pharmaceutical Filling & Processing solution to handle Cell Culture Medium

Aseptic pharmaceutical filling system incorporating the medical and pharmaceutical robot “VS050S2”.This system enables operators to safely and efficiently perform aseptic filling operations while ensuring pharmaceutical product quality, data integrity, and compliance with electronic record regulatory requirements.

-

Artemy® Fully Automated Cluster Harvesting Robot for Mini Tomatoes

DENSO’s FVC team tackles issues like labor shortages and food crises by promoting the industrialization of agriculture.Robots equipped with sensors and cameras automate harvesting for stable food production.

Acces

Venue: Tokyo Big Sight

Address: 3-11-1 Ariake, Koto-ku, Tokyo 135-0063, Japan

TEL: 03-5530-1111