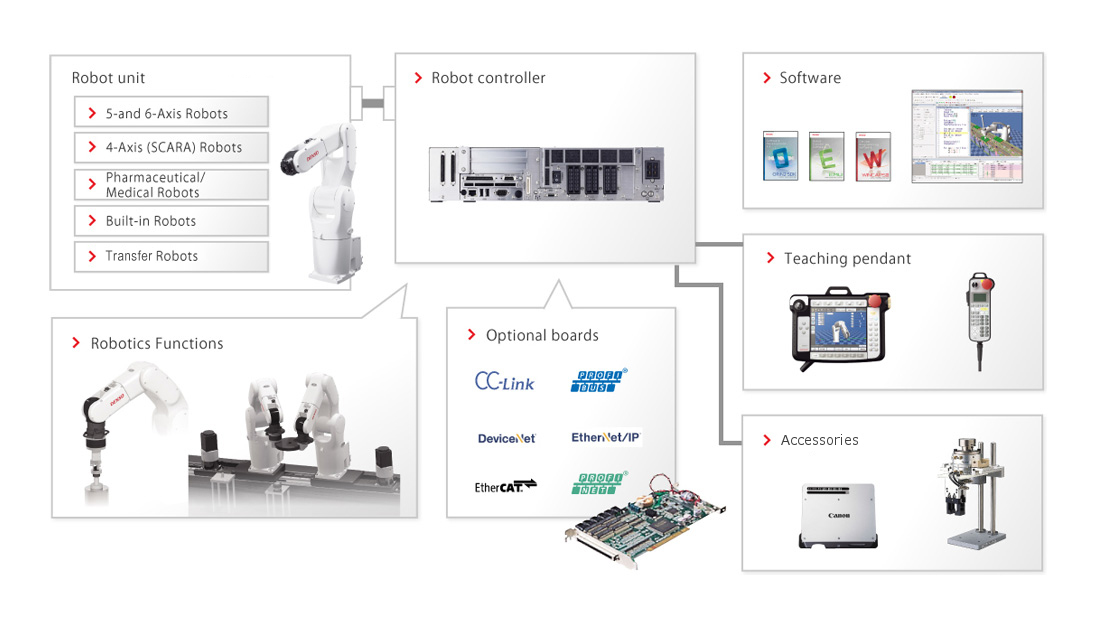

Introduction of a system configuration based on the RC8 controller. Selection of other products and extension of functions are possible according to the customer application.

| Robot | Series | Payload | Maximum Reach | Stroke | Variation | Installation |

|---|---|---|---|---|---|---|

|

COBOTTA | 0.5kg | 342.5mm | ― | ― | Floor-mount |

|

COBOTTA PRO 900/1300 | 6kg/12kg | 1,066mm/1,463mm | ― | Dust- & splash-proof(IP54) Clean |

Floor-mount |

| Robot | Series | Payload | Maximum Reach | Stroke | Variation | Installation |

|---|---|---|---|---|---|---|

|

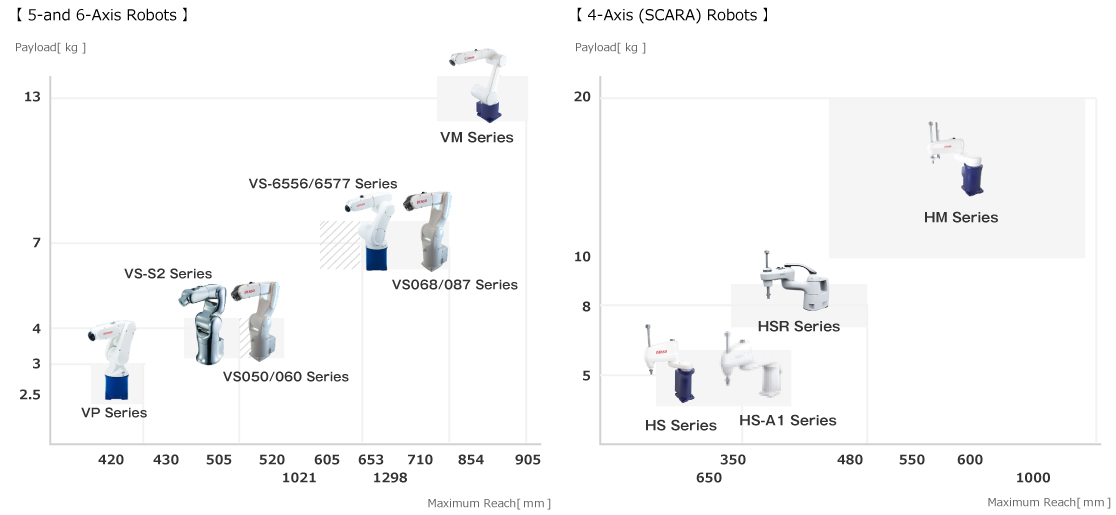

VP Series | 2.5~3kg | 430~432mm | ― | Standard | Floor-mount or Overhead-mount |

|

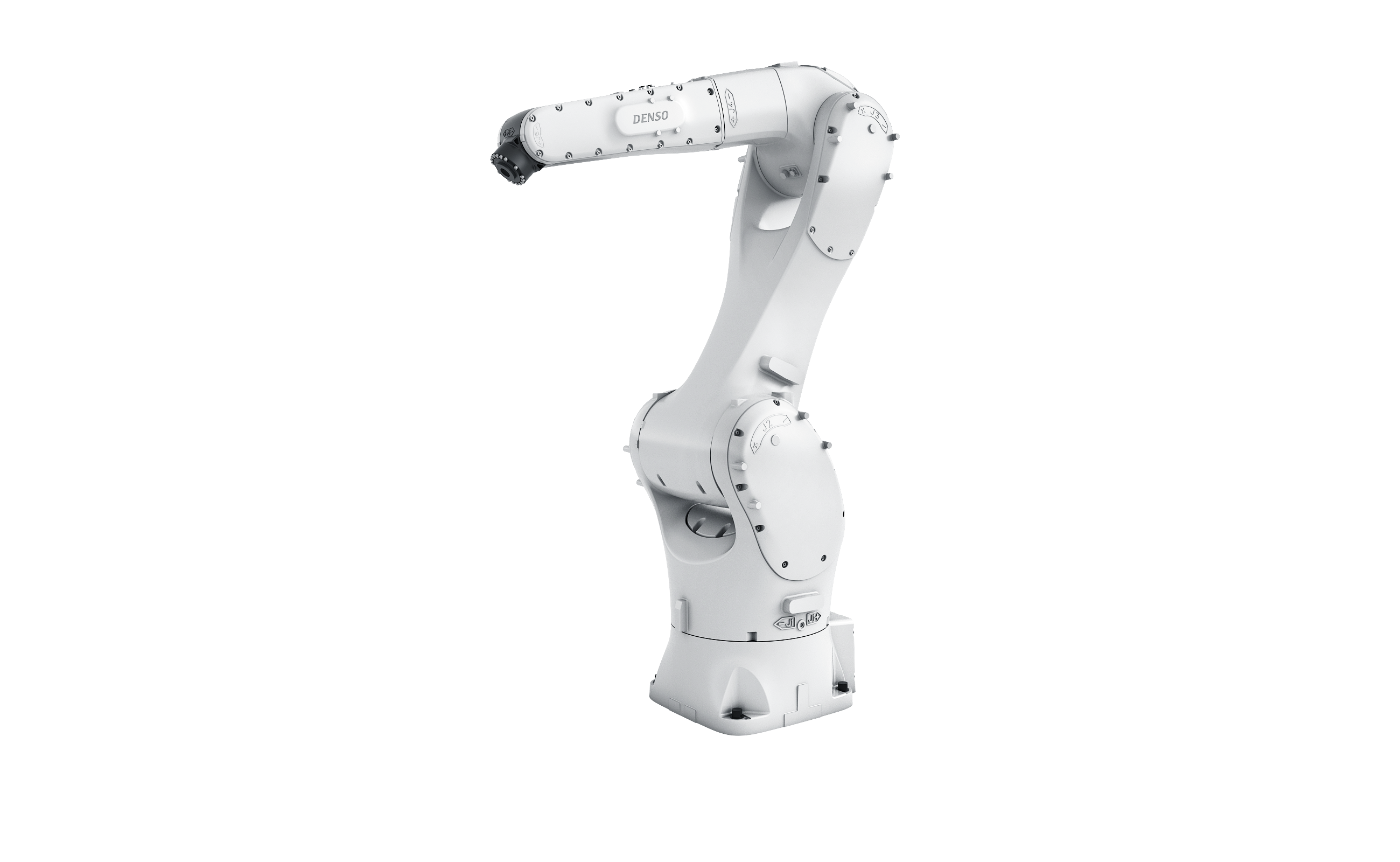

VS050/060 Series | 4kg | 505~605mm | ― | Standard Dust- & splash-proof (IP65) Environment-resistant (IP67) Clean ISO class 5/3 UL |

Floor-mount or Overhead-mount |

|

VS068/087 Series | 7kg | 710~905mm | ― | Standard Dust- & splash-proof (IP65) Environment-resistant (IP67) Clean ISO class 5/3 UL |

Floor-mount or Overhead-mount |

|

VS-6556/6577 Series | 6kg | 653~854mm | ― | Standard Dust- & splash-proof (IP65) Clean 100 Clean 10 |

Floor-mount or Overhead-mount |

|

VM Series | 13kg | 1,021~1,298mm | ― | Standard Dust- & splash-proof (IP65) Clean 100 |

Floor-mount or Overhead-mount |

|

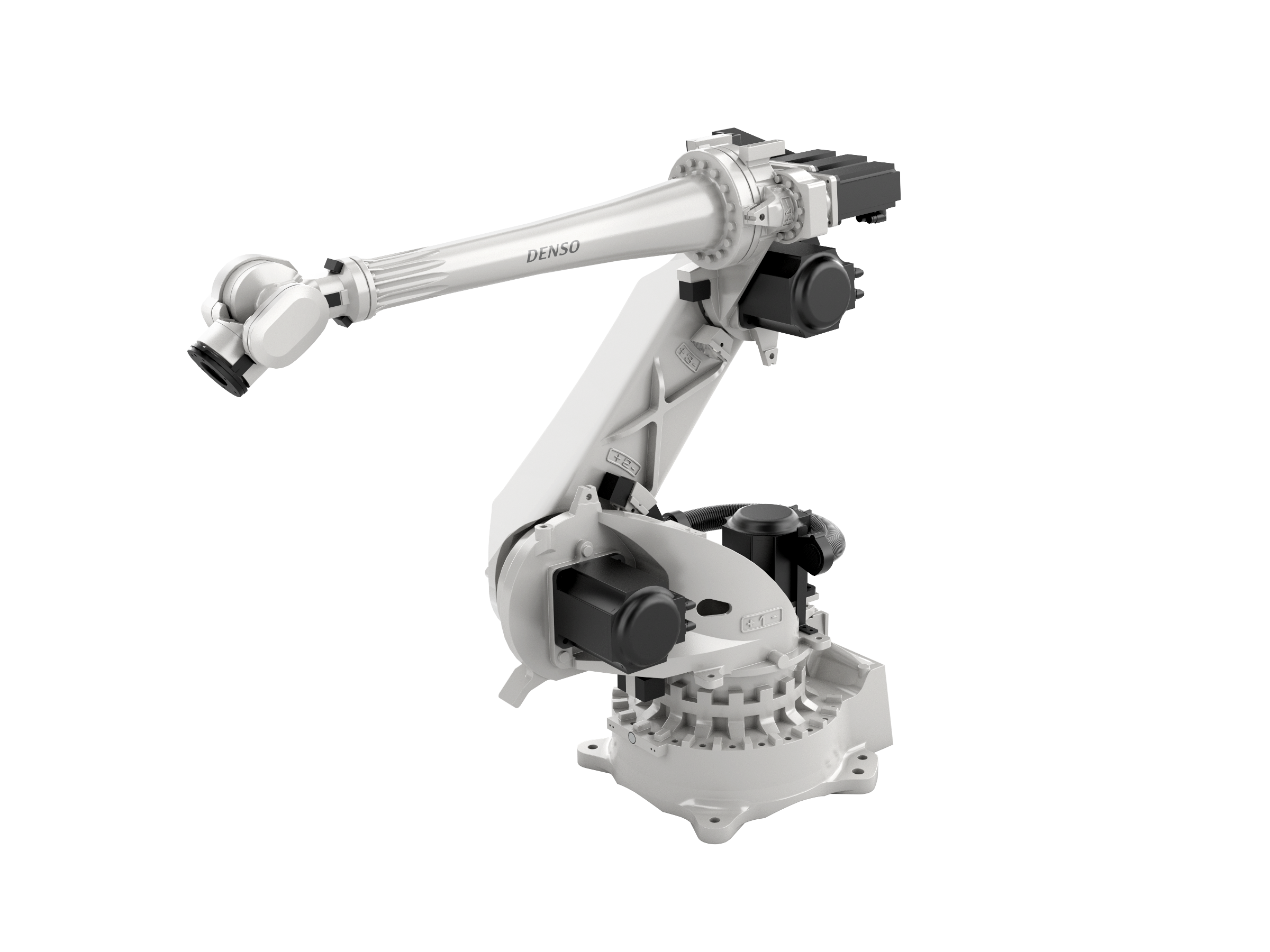

VMB-2515/2518 | 25kg | 1,506mm/1,804mm | ― | Standard Environment-resistant (IP67) Clean ISO class 5 |

Floor-mount |

|

VLA-4025/6022 | 40kg/60kg | 2,503mm/2,257mm | ― | Standard(IP65) | Floor-mount |

|

VS-050S2 Series | 4kg | 520mm | ― | H2O2-proof | Floor-mount or Overhead-mount |

| Robot | Series | Payload | Maximum Reach | Stroke | Variation | Installation |

|---|---|---|---|---|---|---|

|

HSR Series | 8kg | 480~650mm | 100~320mm | Standard | Floor-mount or Overhead-mount |

|

HS-A1 Series | 5kg | 350~550mm | 100~320mm | Standard Bellows Dustproof/splash-proof (IP65) Clean |

Floor-mount or Overhead-mount |

|

HM Series | 10~20kg | 600~1,000mm | 200~400mm | Standard Dust- & splash-proof (IP65) |

Floor-mount or Overhead-mount |

| Robot | Series | Payload | Maximum Reach | Stroke | Variation | Installation |

|---|---|---|---|---|---|---|

|

XR Series | 5kg | X-axis stroke: 450 to 1,060 mm Arm length: 200 to 300 mm |

135~200mm | Standard | Overhead-mount |

| Robot | Series | Payload | Maximum Reach | Stroke | Variation | Installation |

|---|---|---|---|---|---|---|

|

SC Series | Ball-screw type 5kg |

1st axis:600~12,000mm 2nd axis:100~200mm 3rd axis:100~200mm 4th axis:100~200mm |

― | Standard | Floor-mount |

|

SC Series | Expandable type 2~3kg |

1st axis:600~12,000mm 2nd axis:100~400mm 3rd axis:300~400mm 4th axis:300~400mm |

― | Standard | Floor-mount |

If you have not registered

The services on this member site are available only for registered customers.